Rejuvenating Old Car Batteries

Don’t recycle dead batteries without first checking to see if they can be revived

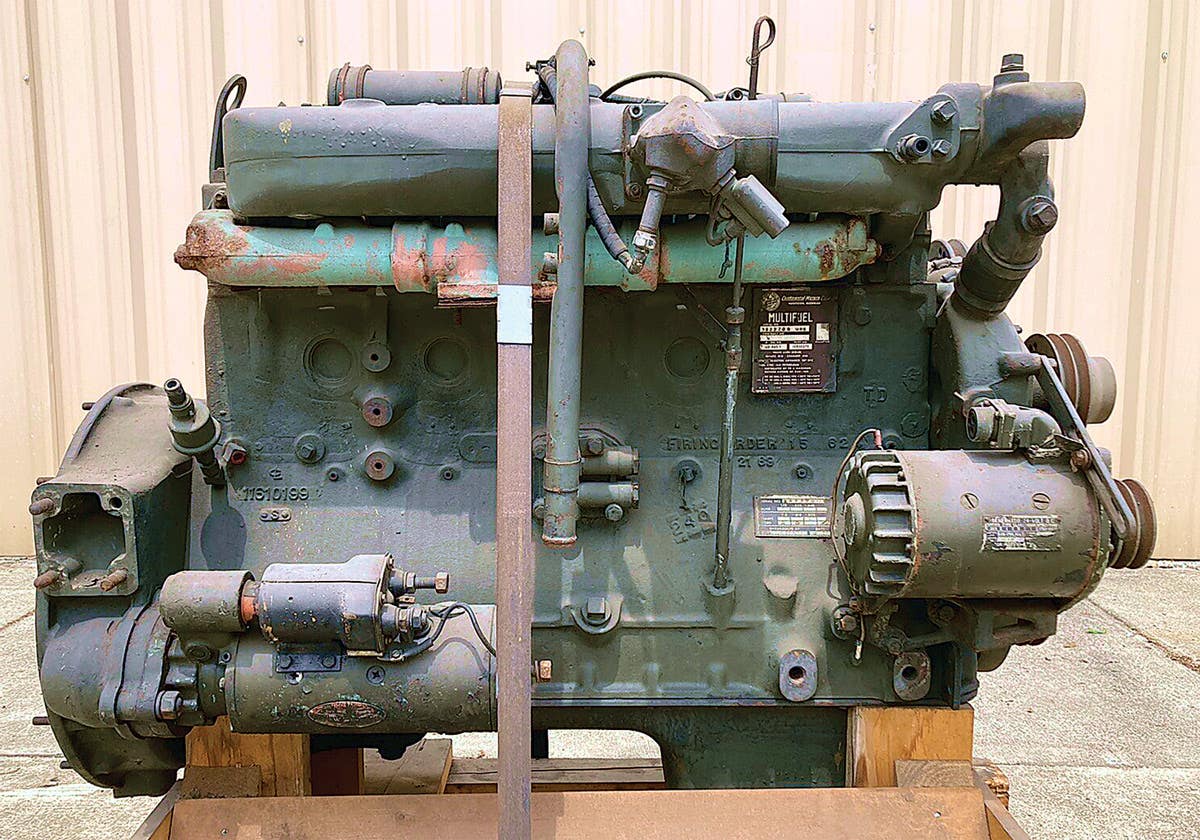

Unfortunately, many collectors aren’t able to drive their classic vehicles as much as they would like. As a result, the vehicles suffer for it. One part of the vehicle that particularly suffers for it is the battery. With many HMVs (historic military vehicles) having two, or in some cases four batteries, some of which are over $100, collectors often take steps to preserve battery life. Some enthusiasts install battery kill switches, trickle chargers, or even remove the batteries entirely to try to prolong battery life.

WHAT CAUSES BATTERIES TO FAIL?

To better understand the cause of these battery failures, one needs to first understand how an automobile battery works. Each battery is composed of cells, three for 6-volt batteries, and six cells in 12-volt batteries. Each cell is made up of a lead plate and a supported lead dioxide plate, both submerged in a sulfuric acid solution. The lead dioxide plate is the positive pole of each cell, while the lead plate is the cell’s negative pole. Contrary to what one may think, the electrons flow from the negative to the positive pole as the battery discharges. As a battery is charged, the flow of the electrons is reversed.

As a battery is discharged, its positive plate is reacted with the sulfuric acid, producing lead ions and water. The negative plate in turn is dissolved, forming lead sulfate as a byproduct. As a battery is charged, the coating of lead sulfate on the positive plate is built up. This process removes water and lead ions from the electrolyte. As this happens, hydrogen is released from the electrolyte and a coating of lead is formed on the negative plate.

Frequently, the cause of a battery’s failure is due to lead sulfate deposits forming on the battery plates. These deposits are formed by the lead ions from the discharge cycle combining with sulfate ions in the electrolyte. As this deposit covers the battery’s plates, it interferes with the battery’s storage capacity.

HOW ABOUT THOSE BATTERY REBUILDERS?

Many of us remember when “battery rebuilders” could be found in many towns, and rebuilt batteries could be bought at your local service station (back when you could get an oil change where you bought fuel, but couldn’t buy canned foods at the same place). While different rebuilders had different processes, the method described below was used by some, and even today continues to prove quite effective.

“REBUILD” YOUR BATTERY

If your battery has loose plates or other physical damage, this method won’t help you. But in the case of sulfated plates, this technique will restore full serviceability to the battery with a minimal cash investment and a little bit of labor. There seems to be almost as many “formulas” as there are battery sizes. While other techniques may work, only the method described here was attempted. It worked so well, the research stopped there!

Before beginning, find some old clothes (spilled battery acid will ruin clothing) and protective equipment, such as rubber gloves and eye protection.

Begin by removing the caps from the battery and emptying it of the old electrolyte. Some people recommend catching the old acid and using it to refill the battery. However, fresh electrolyte is available at better auto parts stores for a nominal sum, so discarding the old acid and using new to refill the battery at the end of the process seems the way to go. In either event, empty the battery into a plastic container (the acid will etch glass and destroy aluminum and some other metals).

Once drained of the acid, rinse the battery with cool water. Observe the water flowing out of the battery, and keep rinsing until no more residue comes out, but only clear water. It may be helpful to gently rotate the battery during this process. Once all the sediment has been flushed out, drain the battery once again.

Now is the time when you will add the “snake oil”—a powder known as “EDTA,” or more properly, ethylenediaminetetraaceticacid tetrasodium salt. EDTA is an organic acid analytical reagent which acts as a chelating agent with metal ions, including the lead ions formed in the discharge cycle of a battery. A chelating agent bonds with these metal ions and holds them in suspension. As you have just learned from the electro-chemical lesson, a battery that spends long periods not fully charged can contain too many lead ions. Show vehicles are prime candidates for this situation, frequently just seeing short trips at low speeds and infrequent use.

When this test began, the only source of supply that the author could locate was an industrial supply firm that sold the chemical in bulk. EDTA has a near infinite shelf life (although it is extremely hydroscopic and must be kept in a dry place), the quantity wouldn’t go to waste.

Add one tablespoon of the chemical to each battery cell, then fill the battery with warm distilled water. Let the battery stand for one hour with this solution in it. Shake the battery once halfway through this process. Drain the battery once again after the hour, and re-rinse it. Again, rinse until the rinse water is clear. At first it will be milky as the EDTA solution leaves the battery, then you will probably get more sediment out. Do not be surprised if this rinse process takes substantially longer than the first rinse did. A 6TL can have a surprising amount of sediment in it.

After you are satisfied with your rinse job, refill the battery with electrolyte and place it on a slow charge. Batteries treated in this manner frequently perform as new for several more years, allowing the owner to spend the dollars saved on other toys!

You may also enjoy

*As an Amazon Associate, Military Trader / Military Vehicles earns from qualifying purchases.

David Doyle's earliest published works were occasional articles in enthusiast publications aimed at the historic military vehicle restoration hobby. This was a natural outlet for a guy whose collection includes several Vietnam-era vehicles such as M62, M123A1C, M35A2, M36A2C, M292A2, M756, and an M764.

By 1999, his writing efforts grew to include regular features in leading periodicals devoted to the hobby both domestically and internationally, appearing regularly in US, English and Polish publications.

In 2003, David received his a commission to write his first book, The Standard Catalog of U.S. Military Vehicles. Since then, several outlets have published more than 100 of his works. While most of these concern historic military hardware, including aircraft and warships, his volumes on military vehicles, meticulously researched by David and his wife Denise, remain the genre for which he is most recognized. This recognition earned life-time achievement in June 2015, when he was presented Military Vehicle Preservation Association (MVPA) bestowed on him the coveted Bart Vanderveen Award in recognition of “...the individual who has contributed the most to the historic preservation of military vehicles worldwide.”

In addition to all of publishing efforts, David is the editor of the MVPA’s magazine, History in Motion, as well as serving as the organization’s Publications Director. He also maintains a retail outlet for his books online and at shows around the U.S.