HMMWV snowplow, a little drip and lacking compensation in this installment of Tech Tips

Something not right with your historic military vehicle? Steve Turchet answers your questions on how to keep ’em movin’!

HMMWV Snowplow

In the recent past, especially in U.S. Army Europe (USAREUR), the Army had extremely limited access to snow removal equipment. The only available implements were graders, the M-9 armored combat earthmover (ACE) and the front-end loader for the small emplacement excavator (SEE). Those tools are specialized and dedicated to specific missions, and attempts to use them for snow and ice control (SNIC) proved detrimental to both the equipment and the areas requiring snow removal. The SEE was designed with snowplowing capability, but snowplows had not been available in the inventory. Also, the SEE was a scarce item and heavily employed where deployed. The High-Mobility Multipurpose Wheeled Vehicle (HMMWV) snowplow enables the HMMWV to rapidly transition from a transportation vehicle to a snow-removal machine.

The plow employs a quick-disconnect system called Minute-Mount; once the mounting brackets and wiring harness have been installed semi-permanently, the plow and all other attachments can be mounted in less than a minute and can be dismounted in half a minute. The mounting brackets require no drilling, cutting, or welding on the HMMWV. Instead, bolt holes in the frame and bumper are used; the wiring harness plugs into the existing lighting harness, and the power cable runs from a solenoid through the firewall to the battery. A controller cable is run through the firewall to the plow control switch, which is mounted on the dash with Velcro. The plow has a fully reversible angle capability of 28 degrees to the right and left, and has ten inches of up and down capability, all of which can be controlled from the driver’s position in the cab. The plow also has an integral trip-edge that folds back and allows the plow to ride over obstacles up to four inches high. When the obstacle is cleared, spring tension is released so that the cutting edge returns to its normal plowing position. HMMWV snowplows are being operated by the U.S. Army in Macedonia, Bosnia, Kosovo, Korea and Germany, as well as at Fort Drum, New York, and at numerous other CONUS locations. To date, some snowplows have accumulated more than 4,000 snowplowing miles during winter seasons without any significant maintenance or operational problems.

A Little Drip

Q: I have a 1958 CJ5 that I have modified to look like an M38A1 with a two-piece windshield, blackout lights and military gauges. The jeep has always dripped a little transmission oil. It was never enough to be a problem, but one day I investigated and found the oil was coming from the back of the transmission top at the shift rod holes. Is this normal? It seems like those holes should not be open. — Jamal Wheeler

A: The holes were originally plugged with pressed-in caps similar to soft plugs in an engine block. What often happens in early model jeeps is that the shift rods wear their bores, gear oil gets behind them, and hydraulic pressure when shifting pops the caps out. Many M38A1 transmissions had screw-in plugs instead of pressed-in caps. However, before installing new caps, you may want to drill small holes in the rod bores to let oil drain back into the transmission. (M38A1 transmissions with screw plugs had such holes.) Otherwise, your new caps may just pop out again, and/or the transmission may be hard to shift because of hydraulic pressure caused by oil trapped behind the rods.

No Compensation

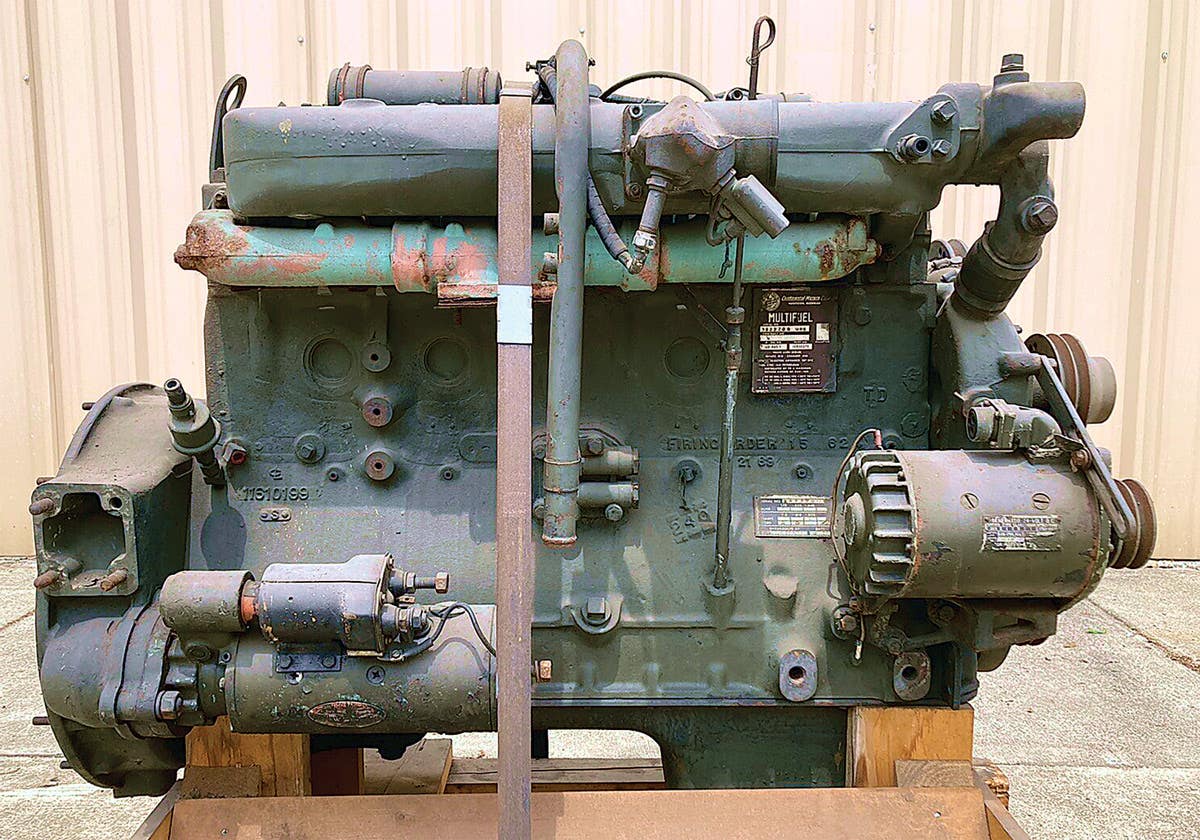

Regarding your recent reply in Military Trader & Vehicles September 2025 issue to Zach Whitmore, I would further one more piece of advice to him. He should bypass the FDC (Fuel Density Compensator). Now before you dismiss me by the third sentence, please just hear me out on the short version. The FDCs leak. They leak fuel directly into the crankcase. This can lead to engine failure. OK, if you are still here, there is more. Yes, the military started and continued to bypass the FDC. My M35A2 was labeled as “Bypassed” with a large sticker from Toole Army Depot. It was not. I ran an oil sample when I purchased it and sent it off to the lab. Results came back with raw diesel fuel contamination in the crankcase oil. I pulled the cover for the FDC and turned on the electric in tank fuel pump. Soon, a steady stream of drips began to come out of the FDC and run directly into the engine. I immediately bypassed the FDC, verified the leak had stopped and changed the oil. I am now 15 years without fuel contamination in my engine oil. Military Vehicles Magazine, December 2002, page 74, has a great diagram and simple instructions on doing the bypass. Adjusting the fuel rod and droop screw are a bit more involved than most people want to get involved in, but the bypass part is important. Of course, if Mr. Whitmore’s truck has no contamination, then he should monitor it from time to time with lab samples to be sure. — John Pattison

In The Bag

No matter how well I equipped my vehicle with emergency repair tools, the toolbox always got stowed neatly away somewhere that made it hard to grab a screwdriver or wrench at a moment’s notice — such as a quick carburetor adjustment or tightening a hose clamp — so I attached a leather handyman’s pouch to the inside of my vehicle’s door and filled it with need-now items such as the favorite screwdriver that fits everything, pliers, wire-cutters, spark plug and other basic wrenches, feeler gauge for ignition points, electrical tape, mini MagLite, etc. I’ve found that most of my roadside repairs can be performed with these tools, and there’s no digging through cartridge boxes or canvas bags when seconds count.

Send your favorite Tech Tip or question to Steve Turchet at military@aimmedia.com

Looking for more Tech Tips? Check these articles out!