A clean sweep: HMV vacuum windshield wipers

HMV vacuum windshield wipers — all you need to know!

Here’s a scenario that may be familiar to many historical military vehicle owners: you’re returning home about dusk after spending a weekend at an HMV show, or returning from a camping trip, in your MB, GPW, M38, M151, M37, M715, G506 or CCKW. The last two days were sunny, but now dark clouds are massing above and raindrops begin to spatter your windshield. As daylight fades, the rain increases. The glass in front of you blurs, and you start to lose sight of the road’s center line. You reach up and pull out the little knob on your windshield wiper motor, but instead of vigorous wiper blade action providing you with much-needed vision, all you get is a sickly hiss while your wiper blade creeps across the glass at the pace of an arthritic snail. Or maybe some hissing is all you get, followed by a feeling of panic as approaching headlights seem to swim toward you as if you were underwater.

Maybe you roll your window down and stick your head out, or lean around the windshield frame while raindrops sting your face and eyes, preferring to be wet and cold to driving half blind in relative comfort while risking a head-on collision. Or, you might grab your wiper motor’s manual handle and flick it to and fro, and continue a juggling act between steering, gear-shifting, and trying to see for the rest of your journey home.

Or, maybe your wiper works all right on level stretches of highway, but slows to a creep or stalls out completely whenever you put your foot on the gas or start to climb a hill?

Mention vacuum windshield wipers to most people who still recall when they were standard equipment on most civilian cars and trucks and you’ll often get colorful adjectives. Discuss vacuum wipers with fellow HMV owners, and you’ll often get the same adjectives, along with opinions to replace them with electric units. While going electric might be one way to clear your vision -- assuming you’re not a purist to the point where you’d rather play hide-and-seek with oncoming traffic instead of putting non OEM parts on your vehicle -- this sometimes expensive move can often be avoided by checking out your vacuum wiper system, performing some simple repairs or replacements, and doing occasional maintenance.

Wiper system? You might think that’s a grandiose term for those little pot-metal contraptions mounted above, or below, your vehicle’s windshield. But, like most things automotive, there’s a lot more to what makes a vacuum wiper wipe than just what you can see — those motors and sections of hose and tubing on your windshield frame. In fact, you might be surprised to learn that many times your wiper problems aren’t the fault of the motors. So, before considering the work and expense of replacing your HMV’s vacuum wipers with an electric system -— and often discovering that the price of good quality electric motors will really cause your vision to blur — you might want to read this article. You may find you can live quite well with your vehicle’s stock vacuum wipers.

I apologize for my rough illustration, but in 60-plus years of being a mechanic I have yet to find a decent depiction of a complete vacuum windshield wiper system. Even the “U.S. Military’s Principles of Automotive Vehicles”, a bible of great information and a book every HMV enthusiast should own, doesn’t deal with windshield wipers. This surprises me, because dependable windshield wipers are pretty important things to have, especially in combat! Maybe, like that song about the Arkansas Traveler who meets the old man with a leaky cabin roof, we only think about windshield wipers when it’s raining and they aren’t working right, but as soon as the sun comes out we forget how important they are.

A bit of history: the very first cars and trucks didn’t have windshield wipers -- assuming they even had windshields -- but this wasn’t much of a problem since average vehicle speeds seldom exceeded 35 mph. Instead, most vehicles had two-piece windshields, split horizontally at the driver’s eye level. Few people today, even some owners of antique cars, know why the upper halves of these windshields could be opened outward like a visor. This was not primarily for ventilation on hot summer days: instead, the reason these windshields opened was so the driver could see when it rained. At slow speeds very little rain got in, unless a wind was blowing.

Like most people, I had never considered this aspect of having a windshield that opened, until I ran across an old advertisement for Reo trucks that touted their “Rain-Vision Windshields.” To some extent this was also the reason why most WWII vintage military vehicles had windshield glass that opened outward.

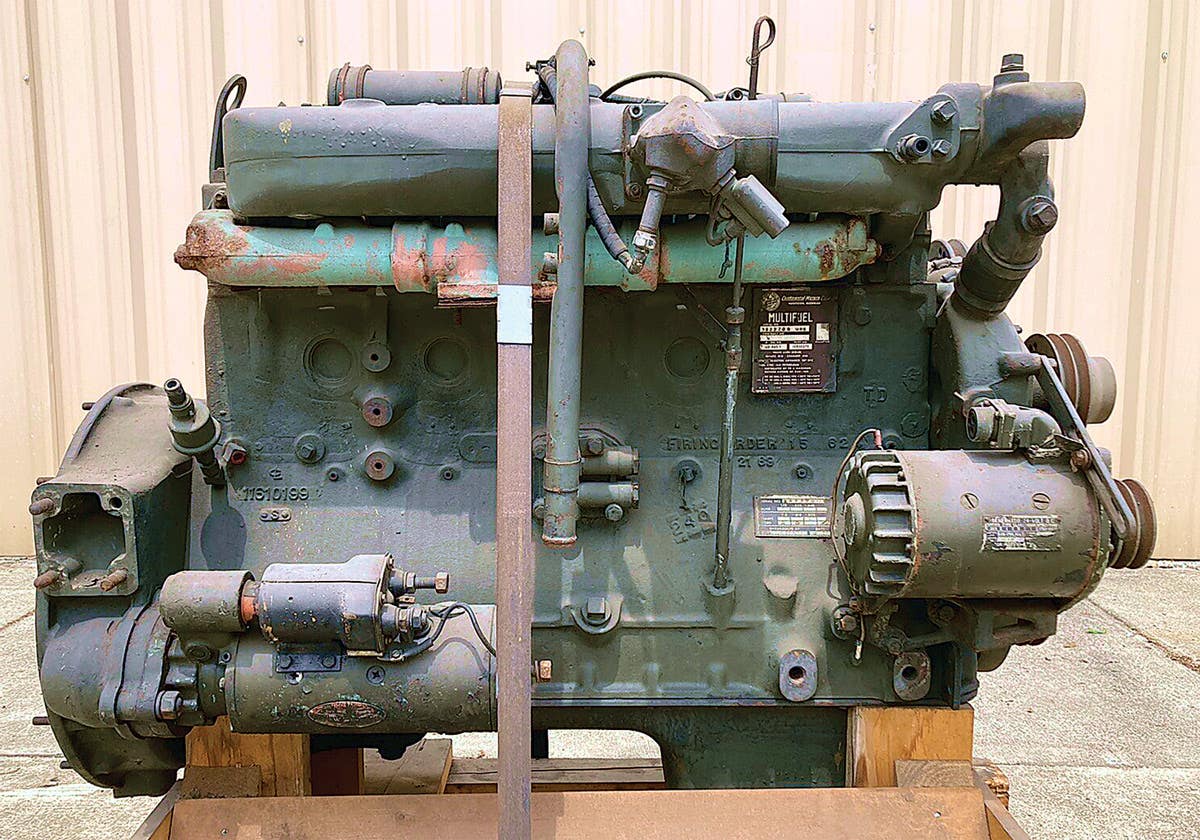

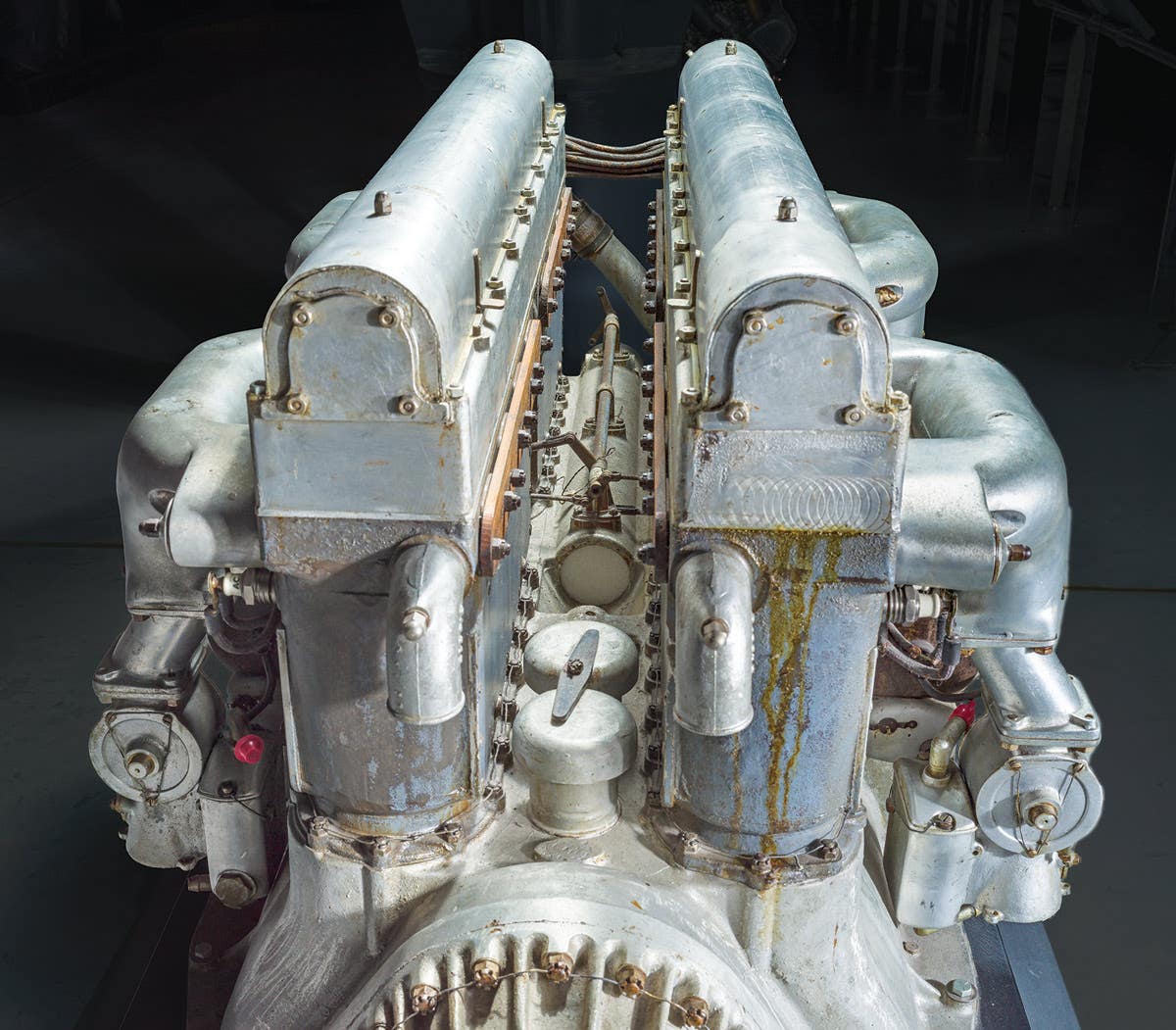

The very first windshield wipers were hand operated just like on early model WWII jeeps. This was adequate for slow speeds and short distances; but using a hand-wiper quickly becomes tedious as well as inconvenient and distracting when you have to simultaneously steer your vehicle and shift gears while using one hand in order to see. While it’s logical to assume that vacuum wiper motors were the first automatic devices invented to keep a windshield clear, both electric and vacuum motors began to appear at about the same time. Vacuum wiper motors predominated on most U.S. cars and light trucks up until the late 1950s, while larger vehicles, especially busses, used electric motors. This wasn’t so much because electric motors were more reliable than vacuum models, but rather because the operation of electric wipers is more consistent, being they don’t stall out on long upgrades or under demanding engine loads. Heavier vehicles with air brake systems generally used air-operated wiper motors, such as those on M-series deuces and 5-tons, though I’ve seen exceptions on some medium-duty trucks where air brakes were offered as optional equipment, and electric wipers were fitted in either case. Electric wipers were also usually stock on medium trucks where a diesel engine was optional, because diesel engines don’t provide the necessary manifold vacuum to operate vacuum wipers. In a few cases, a vacuum pump was fitted to diesel engines to operate vacuum wipers.

Wipers work equally well whether mounted above or below the windshield, but the strangest setup I ever saw was on an ancient city bus where the wiper blades were mounted on tracks with rollers and wiped horizontally side-to-side. And, there are Clear-Vision ports with a spinning glass disk that whirls the rain and snow away, as used on ships and some snowplows and railroad locomotives.

That just about covers windshield wiper history 101.

Running stock vacuum wipers on your HMV can often work very well if you keep your system well maintained. After all, most of these systems worked fine when your vehicle left its factory. I had no problems with my M38’s (my first jeep) vacuum wipers, maybe because I didn’t know how “inadequate” they were supposed to be.

So, if vacuum wiper problems are causing your vision to swim, let’s see what we can do to clear things up.

First, check out the rough diagram of a basic vacuum wiper system, and you might be surprised to find that a vehicle’s fuel pump plays a major role in how well this system works. You might also be surprised at how many letters I got when an early version of this article appeared way back in Military Vehicles Magazine #19 from folks who’d been cursing their vacuum wipers for years while never knowing their vehicles’ fuel pumps were supposed to be involved. Why? Because oftentimes the stock double-acting (compound) fuel pumps of many military surplus vehicles were replaced by less- expensive single-acting civilian models, and the hose or tube to the wiper motor(s) was connected directly to the engine’s intake manifold. Doing this provides plenty of vacuum to operate the wipers when a vehicle is idling, cruising level highway or coasting downhill, but as soon as you accelerate hard or pull a long grade, the manifold vacuum drops and your wiper stops wiping.

On the other hand, a double-acting or compound fuel pump maintains a steady source of vacuum for the wipers no matter what the vacuum might be in the engine’s intake manifold; and that’s why you need this type of pump if your vehicle has vacuum wipers.

If you find that your “stock” HMV doesn’t have a double-acting fuel pump, and you have vacuum wipers, installing the correct pump should clear up your vision considerably. I once got a letter from a puzzled individual who had just installed an electric fuel pump on his M38A1 and had removed the mechanical pump, and wanted to know why his wipers had stopped working properly.

Of course, this isn’t always the problem — or all of it, anyway — and compound fuel pumps can fail on the vacuum side while still pumping fuel, so, assuming your wipers aren’t working right, let’s check out the system in logical order, beginning at the source. A vacuum gauge will be handy, but you don’t need to buy a fancy test gauge: any vacuum gauge will do... just attach a suitable piece of hose.

I’m assuming you’ve already checked for obvious vacuum leaks in the system, like hissing hoses — when the engine is idling — or hissing from the wiper motor’s control valve or switch. Naturally, you will have already replaced any leaky or deteriorated hoses and lines, as well as checked all their fittings for tightness. That’s basic maintenance.

So, what is vacuum and where does it come from? For practical purposes on this planet, vacuum could simply be called the absence of air or the pressure thereof. In the case of most gasoline-powered HMVs, the primary source of vacuum for the wipers comes from the engine’s intake manifold, and is provided by the pistons going down on their intake strokes, so the manifold is the logical place to begin your testing. With the engine idling, remove the intake manifold to fuel pump hose (or tube) from the manifold fitting. You should hear a hiss of air being sucked in, and the engine will falter or even die. This tells you that the manifold fitting is open and not clogged with crud. Connect your vacuum gauge to the fitting. If your engine is in good shape and properly timed, you should get a steady reading of around 15 to 20 inches of vacuum at idle. If the gauge needle fluctuates rhythmically, this could indicate engine problems such as a misfiring spark plug or a leaky valve, but that’s another topic altogether.

Now, reconnect the intake manifold to fuel pump hose or fitting, start the engine, and remove the fuel pump to wiper motor hose from the wiper motor’s vacuum inlet. Again, you should hear a hiss, and the engine will falter. Connect your gauge to the hose or tube, and you should get about the same reading you got from the engine’s intake manifold. It’s still possible that the vacuum side of the fuel pump has failed or is weak. A good way to check this is to leave your gauge connected and take your vehicle for a drive. The vacuum will drop when you accelerate, but if the pump is working properly there should still be some available for the wiper. If the vacuum drops to zero on acceleration, then you’ll probably need to replace or rebuild the fuel pump.

Rebuild kits for most common double-acting fuel pumps, such as Carter or Airtex, may be found on the Web. An important thing to remember is that most of these pumps are basically the same, the primary difference being the shape and length of the actuating arm as required for a specific engine. In other words, most of these pumps use the same diaphragms and internal components. For example, many rebuild kits for vintage Carter fuel pumps specify only “six bolt” or “eight bolt” (referring to the number of bolts that hold the pump together regardless of vehicle, or engine make or model.

Likewise, if you want to replace your single-acting pump with a double-acting model but can’t find a listing for your vehicle or engine, you may simply be able to switch the actuating arm to make another pump work. In addition, some double-acting pumps may be indexed in regard to their fuel inlet and outlet fittings to fit different applications.

If you opt to rebuild a fuel pump yourself, make sure the rebuild kit has modern parts, because many vintage NOS kits have deteriorated in storage and their diaphragms and gaskets are probably not compatible with today’s ethanol-blended gasoline.

On the other hand, if some vacuum is maintained on acceleration or hill climbing, this tells you that your wiper problems are likely in either the motor itself, or possibly the wiper shaft is rusted, bent, or jammed with dirt.

By the way, if you want to install a permanent vacuum gauge in your vehicle, it should be connected directly to the engine’s intake manifold and not to the windshield wiper line.

If the problem seems to be in the wiper motor(s), first remove the wiper blade arm from the wiper shaft. Wiper arms are attached to the shaft in various ways, sometimes using a clamping screw, sometimes with a nut, sometimes with a serrated fitting, or sometimes the entire arm assembly is pressed onto the motor shaft, as is the case with early M151s. While removal should be obvious, it’s common to find that the nut or clamp screw is badly rusted, requiring patience and skill to remove without breaking or damaging it. A small pinpoint torch can often be helpful to carefully heat the frozen part.

Once the wiper arm is off, examine the motor shaft to see if it’s rusty, bent, or jammed with dirt. If bent, you may be able to straighten. You might also want to investigate how it got bent in the first place, especially on vehicles such as jeeps with fold-down windshields. A wire brush should deal with any rust; and the shaft can be cleaned and lubricated by spraying with WD-40 or brake or electric motor cleaner, followed by a few drops of engine oil. After this is done, start the engine and check for improved wiper action. If your wiper still isn’t wiping right, the motor may simply be worn out, necessitating repair or replacement. However, you can try removing the hose from the vacuum inlet, then open the control valve and spray in some WD-40 while working the manual handle back and forth. (You should do this every so often anyhow because it’s good preventive maintenance, along with oiling the wiper shaft.) Reconnect the vacuum hose, start the engine, and see if the wiper action improves. If it doesn’t, then you will probably need to repair or replace the wiper motor.

While it is possible to disassemble and clean many types of vacuum wiper motors, I have seldom seen repair kits offered on the retail market, though a search on the Internet might bring results. There are companies that advertise on the Web and specialize in rebuilding vacuum wiper motors. In addition, some companies that advertise in this magazine offer NOS early model M151 wiper motors for reasonable prices. (I have two of these motors in my 1965 Nissan Patrol.)

While not “correct” for many other HMVs, these motors are a good value and have nice manual-actuating levers, and may be mounted either above or below a windshield. One minor disadvantage is they don’t have a built-in control valve, but I use small screw valves on mine.

However, it may be more trouble than you think it’s worth to try to repair or rebuild your old unit. Of course, if you like to tinker with stuff, then by all means go ahead. If the motor’s control valve is leaking — indicated by hissing — it can sometimes be fixed by disassembling and cleaning the unit, but, again, this might not be worth your time.

On the other hand, and if you’re still contemplating an electric system, I’ve seen heavy-duty 24-volt electric motors advertised for as high as $500. Of course, there are much cheaper models, but you’ll usually get what you pay for when it comes to electric wiper motors. I once bought a blister-packed 12-volt marine windshield wiper kit for about $40, and besides having a very limited blade swing of about 70 degrees (90 degrees is generally best), it made a lot of noise when running and interfered with my radio. Worse, I bought an electric motor from a certain famous mail-order auto parts house and was surprised that anyone would bother to build such a piece of junk.

Another option for running a reliable vacuum wiper system is installing an electric vacuum pump, but be sure to get a good one designed for continuous operation. Many inexpensive electric vacuum pumps, such as those for vacuum controls on SUVs, are meant only for intermittent use and will quickly overheat and burn out in continuous operation.

A vacuum reserve tank is also viable, though with a double-acting fuel pump and wiper motors in good shape, you shouldn’t need one.

If you’re still determined to go electric, checking out swap meets, flea markets, or truck wrecking yards should get you a good set of electric motors at a fairly reasonable price. Naturally you’ll want to try them out before buying them. Electric wiper motors from delivery trucks or postal vans are usually heavy-duty units and will give many years of service. Another possibility are rear window wipers from modern cars and SUVs. If your HMV has a 24-volt electrical system, you can still run 12-volt wipers by either using a resistor or taking a hot wire from the “first” battery. If your vehicle has a 6-volt system, your choice of electric motors will be more limited, though, again, searching the Web and venues such as Ebay should bring results. I once owned an M38A1 with an electric wiper on the driver’s side and the stock vacuum wiper on the passenger side. This setup worked very well for me because I seldom use the passenger side wiper anyway. This might be the way to go if you want an electric wiper but have a limited budget. A simple trick to make electric wipers look more correct on your HMV -- besides painting them OD -- is to run the wires though the old vacuum lines.

Naturally, if you have a restored HMV, or are planning to restore one, you’ll want to be sure a replacement wiper motor is correct for your particular vehicle.

By the way, most of the trouble-shooting procedures for vacuum wiper motors offered here will also work on the air operated wiper motors found on later model DUKWS, M-series deuces and larger trucks.

When replacing a vacuum wiper motor, I’ve found that it’s usually best to buy a new wiper arm at the same time. There are many subtle differences in wiper motors and wiper arms (we’ll get to the wiper blades in a moment), and while these differences may seem slight, they can cause major frustration because dealing with wiper motors, arms and blades is kind of like doing watch repair — those little parts may look very much alike but will seldom, if ever, interchange.

And this goes double for arms and blades.

While these little differences in wiper arms and blades may indeed seem trivial at first glance, you’ll quickly find that they’re anything but. This is especially true when it comes to how the blades attach to the wiper arms: this attachment might look simple but it has to be correct, and the various types will not interchange. Trying to improvise, or modify a blade or arm seldom works: either the blade won’t wipe like it should, or it simply falls off.

If you do attempt to modify a wiper arm, be sure to get the spring tension (which holds the blade against the windshield) correct. Too little tension and the blade won’t wipe the glass, and will also be wind lifted at higher speeds. Too much tension and the rubber of the blade will be distorted and won’t wipe cleanly.

I’ve found that catalogs, charts, and interchange information about wiper blades and arms are usually just about worthless. There are two main manufacturers of vacuum wiper motors, blades and arms in the U.S., Trico and Anco; and sometime during the 1970s they both began a major house-cleaning and discontinuation of older components and parts. For a while both companies offered adaptor kits, enabling you to use more modern blades and arms on older vehicles, but then even the companies themselves got confused about what would fit which application. Not only that, but each company seemed to want make sure that their competitor’s parts would not interchange with their own. That’s why I suggest buying a new wiper arm if you’re going to replace a wiper motor, and hopefully a new blade as well.

If ordering by mail or off the Web, be sure the seller knows what they’re talking about if they say the motor, arm and blade will all work together and be the right type for your vehicle. If, for example, somebody tries to tell you that “all old jeeps use the same windshield wipers”, then I’d suggest shopping elsewhere.

An important thing to check is the length of the wiper motor’s shaft, which is sometimes also the motor’s main mounting point. If the shaft is too short then it won’t fit through your vehicle’s windshield frame, and if it’s too long the wiper won’t wipe properly.

For those who like ancient history, the Trico S583 series wiper motors (with some exceptions) were used on the MB, GPW, M37, CCKW (open cab) the early DUKW (with vacuum instead of air wipers) many open cab I.H.C. vehicles, and most Dodge WC trucks, including the 6X6. These motors had an integral control valve (switch) and a short manual handle.

Trico KSB series motors (with some exceptions) were used on the half-ton Dodges, some WCs (closed cabs) the CCKW closed cab trucks, and the Chevy G506. These also had an integral control valve (though the valve’s location varied) but no manual handle.

Trico SK527 series wiper motors were used on the M38, M422, M715, and M151. These motors had no integral control valve, but featured a long handle for manual operation. (These are the motors I have on my Patrol.)

Keep in mind that these are series motors and have differences within the series for various applications, such as wiper shaft length, type of mounting, degree of blade sweep, parking position (left or right) and location of the control valve; so if you’re restoring your vehicle it would be best to visit a few HMV shows to see what style of motor, arm, and blade is correct for your own application.

Generally speaking, the same basic type of wiper blade was used on most U.S. tactical military vehicles from the early 1940s up until the early 1970s. This was the Trico U778 series, and was also used on some civilian cars and trucks. It was a straight blade designed for wiping flat glass. Early types were mounted to the wiper arm by a hook, while later types had a set- screw, similar to early Volkswagen wipers, and other types had a small thru-bolt. These blades are seldom found today in auto parts stores; and beware when ordering NOS blades by mail or online because the rubber has usually deteriorated to the point where they won’t wipe properly. However, the Web is a great source for straight repro blades in various lengths. (I use repro hook type 6” blades.)

Blade length is also important to how well your wipers wipe: obviously, the longer the blade, the more it resists being moved across the glass by the motor. “Correctness” notwithstanding, one should choose the shortest blade that provides adequate vision.

You can often adapt early model Volkswagen blades to fit your set-screw arms, and I’ve had success replacing the thru-bolt type blades with larger straight commercial truck models by cutting the blade to the correct length. Marine supply houses are often a good source for straight windshield wiper blades, though some marine blades are made of vinyl instead of rubber and don’t wipe very well in vehicular applications. Likewise, the quality of reproduction blades varies widely.

More modern blades, such as the Trico TAU series and Anco 325 series can sometimes be used on older HMVs, either with the proper replacement arm, or if you’re lucky enough to find an adaptor kit. Naturally, these aren’t correct if you’re fully restoring your vehicle, but a little OD paint will give them a military look. There used to be an adaptor kit from Anco (#33790) that allowed you use the more modern Anco 325 series blades on older arms. Anco 525 series blades could also be used with this kit, though these blades were meant for curved windshields and don’t work as well on flat glass. A lot of Model A Ford parts dealers still have the proper style U778 wiper blades —- usually reproduction -— but a Model A blade may be too short for some HMV applications.

By the way, the proper blade lengths for most common collectable U.S. HMVs are 8 1/4”, 9”, 10’, 11” and 12”.

Again, a search of the Web should get you what you need... and often what you really want.

While this just about covers the trouble-shooting and repair procedures for HMV vacuum windshield wipers, here are a few other tips for maintaining clear vision:

It’s good practice to replace your wiper blades about every two years, especially if your vehicle is used a lot or is parked outside, because sunlight rots wiper blade rubber. There used to be something called wiper blade dressing, which preserved and even restored old blades, and you might give that a try if you can find any. Another trick is to gently sand the blades with fine sandpaper or emery cloth. I’ve found pros and cons to using “Rain X”: it seems to work better when you don’t use your wipers, but tends to streak the glass if you do.

Another major factor in clear vision, and one that a lot of people don’t consider, is that an aged windshield has thousands of tiny pits and scratches, and oncoming headlights at night make a mosaic of diffused glare which can seriously hamper your sight. If you’ve been experiencing this sort of thing, it might be wise to get new glass. This will not only improve your vision but will make your HMV look better, too.