Deuces wild, parking brake service, vanishing oil and more in this installment of Tech Tips

Something not right with your historic military vehicle? Steve Turchet answers your questions on how to keep ’em movin’!

M38 Matters

Q: I wear out the pages reading your Tech Tips. I’m a small-time Jeeper since the 1950s, mostly CJ-2s, M38s and M38A1s. A question about my M38: when I back up, the brakes lock. Pull forward and it’s OK. I put brakes on it three or four years ago. Before I pull the brake drums I wanted to hear from you. My transmission shifts OK, except sometimes it’s hard to get it from 4-wheel drive back into 2-wheel drive. If I stop and go into reverse with a little clutch movement, it slips into 2-wheel drive and away I go. I broke down in Prescott, Ariz. a few years back with my M38 ... naturally at 5:30 p.m. at a stoplight. The jeep had no spark. After a couple of days checking and rechecking and wearing out all the Irish bloopers I knew, a friend of mine suggested it was the capacitor in the distributor. All-knowing me said they never break down. I had to eat those words! Also, my M38 has never had a working instrument cluster.

Keep on writing the good stuff. —R.L. White

A: Thank you for your kind words about Tech Tips. In regard to your question about the brakes locking when you back up your M38, first, are you sure it’s the brakes? There are cases where the main-shaft in the transmission becomes loose, either because of badly worn bearings or the nut on the output gear to the transfer case backing off, which may cause a jamming condition in reverse. This has also occurred on other vehicles such as early Nissan Patrols. If you’re sure the problem is in the brakes, it sounds as if something in the brake shoe mechanism is either missing, broken, or incorrectly installed. If you have a manual this should be easy to spot. Also make sure you have the correct shoes for your jeep. Some drum brake systems have a leading shoe and a trailing shoe, so also make sure these are correct. It’s also possible that the brake shoe return springs have lost their proper tension from being overheated or because of simple old age. Most modern drum brakes (“modern” includes your M38) are self-energizing. This means that after one steps on the brake pedal and the shoes make first contact with the rotating drum, they are pulled tighter against the drum by its rotation. So, if something is broken, missing, incorrectly installed — or if the shoe return springs are weak — one or more of the brake shoes may be pulled into tight contact with the drum when you’re backing up, causing them to jam. With this in mind, I would first make sure — with a manual — that everything is installed correctly in the brake shoe mechanisms, and that the shoes are adjusted properly so they don’t drag on the drum.

If all seems OK in this respect, my next move would be to install new shoe return springs and see if this solves the problem. Oil or grease on the brake drums may also cause the shoes to jam, as can dirt or sand in the drums, as well as corroded or sticky wheel cylinders. It’s normal for the drive-train to build up tension in four-wheel drive, which can make it hard to shift out of four-wheel drive. Likewise, it may be difficult to unlock locking hubs. I discovered this on my first jeep, an M38. I also discovered that backing up a little way — 10 feet or so — usually released this tension, making it easy to shift out of four-wheel drive as well as unlock the hubs. In regard to the capacitors or resistors in M Series waterproof distributors (or any other distributors, for that matter) they all eventually fail, so it’s a smart idea to carry spares. Badly burned ignition points are one indication that a capacitor — often called a condenser — has failed or is failing.

As to your M38’s instrument cluster, if none of the gauges work (except, I assume, the speedometer) I would first suspect a bad ground between the instrument panel and the dashboard. If the panel turned out to be properly grounded to the dashboard, I would then check that each gauge is properly grounded to the panel by removing the mounting brackets and cleaning them to be sure they were making good metal-to-metal contact. If that didn’t work, I would then check that all the gauges get power when the ignition switch is turned on.

After that, one would have to start testing individual wires to each gauge and to the sending units. And, though it seems unlikely, there is a possibility that all the gauges are bad. Lastly, one would check the sending units.

Compensating For Something?

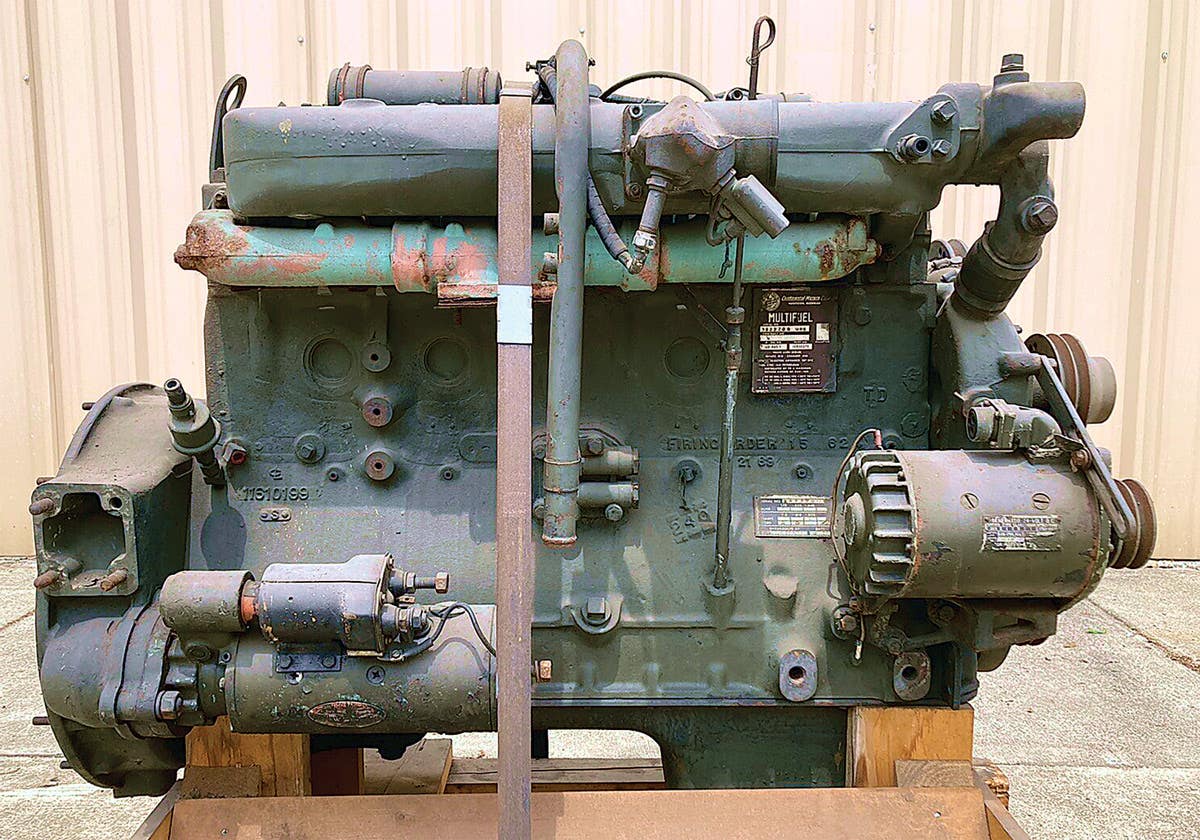

Q: I just bought a 1967 M35A1 with a multifuel engine. The truck was used on a farm, but not very much and is almost completely stock. I am going to restore it to a Vietnam appearance. The engine runs well, has lots of power and doesn’t smoke a lot, but I started getting advice on military vehicle websites to adjust or bypass the “compensator” to get more power. What is the compensator, and should I mess with it? —Zach Whitmore

A: For some folks, getting an M35 style deuce is like installing a new browser or application program; they seem to want to jump right to Advanced or Custom settings without first finding out if the default setting might serve them just as well, or maybe even better. With multifuel deuces, it sometimes seems to be forgotten or ignored that, except for a few faults and quirks, they were one of the best military trucks in the world. There are many conflicting opinions and advice about compensators on multifuel engines; and with free advice — including mine — one usually gets what they’ve paid for. Anyway, during the latter part of the 1950s, concerned about the potential devastation of nuclear war and the resulting havoc to supply systems, the U.S. military wanted vehicles that could run on several different kinds of fuels, such as diesel, gasoline, kerosene and jet fuel ... even antifreeze mixed with engine oil.

Although the Reo Truck Company, which had originally designed and built the M35 (or G742 family of vehicles), submitted a design for a multifuel engine, the contract was awarded to Continental, which built so-called Hypercycle engines under license from M.A.N. of Germany. There were several models of these engines, and the fuel-injection pumps on most but the early LDS-427 were equipped with a fuel density compensator. This compensator varied the fuel delivery rate when different fuels were used. Basically, it allowed the engine to perform about the same no matter what kind of fuel was used—though the best and preferred fuel was always diesel. Normally, no adjustments were needed when changing or mixing fuels. In theory, the trucks were simply fueled with whatever approved fuels were available, including a mix if necessary, and then went out on their missions. In practice, this wasn’t entirely successful; but since — thankfully a nuclear war didn’t happen, there was usually an adequate supply of diesel fuel so the engines’ multifuel capabilities were seldom tested. In fact, toward the end of the multifuel era, the fuel density compensators on some vehicles were bypassed, and the engines were then supposed to be run on diesel fuel only, although there were usually directions on how to reactivate the compensator if needed.

You will get tons of advice on this topic some of it good, some of it not so good. Mine is this: If it ain’t broke, don’t try to fix it. If your engine is running well, seems to have sufficient power and doesn’t smoke much, it might be best to leave the default setting in place and just enjoy your new deuce. I’m sure you’ll find plenty to work on without messing with the compensator. Of course, get service and operation manuals.

Good Old Deuces

Q: I enjoy all of your articles and tips. I want to buy a Korean War M35 deuce-and-a-half and restore it. I have seen lots of M35s for sale in your magazine and also at MV shows but most of them are either newer diesel-powered trucks or multifuel powered from the late 1960s and early 1970s. I haven’t seen a gas-powered deuce-and-a-half at any shows I have gone to. Was there something wrong with these trucks? —D. DeFassio

A: Thank you for your kind words about my writing. For their time — the 1950s and early 1960s — the Reo 2 1/2-ton trucks, first powered by the Reo OA 331 gasoline engine, then the COA 331 (which was the same engine built by Continental.) were very rugged and dependable vehicles. The engines had replaceable cylinder sleeves and seven main bearings, and were extensively used in the civilian trucking industry during those times, including in the White Compact. Though underpowered by today’s standards, there was nothing wrong”with the first M35s, which soldiered very successfully through the Korean War into Vietnam. I personally owned one and have driven many others. If I was going to restore an M35 style deuce it would be one of these. As you say, there doesn’t seem to be many restored examples, as most folks seem to opt for either the multifuels or later straight diesel-powered units, and it would be nice to see a good example of this seemingly neglected era of M35 history.

Building A Better Deuce

Q: About a year ago I bought a 1956 Reo M35. I use it for hauling wood sometimes, but mostly it’s my big Tonka toy. Gas mileage sucks, and the rear wheels seem to he fighting each other all the time, even though I have matched all the tires. I’m a pretty good mechanic and I was wondering if anyone had ever tried to install an inter-axle differential in a deuce? —Ben

A: I did. By accident, I found a tandem drive axle setup with an inter-axle differential on a junked Reo cement mixer truck. The axles were Rockwells like the Reo deuces, but were mounted to a Hendrickson bogey. I found that the ratio was the same as the M35’s. Although the mounts on the axles required some modifications, the M35’s hydraulic brake assemblies bolted right in place of the concrete mixer’s straight air brakes. I mounted the manual air control for locking the differentials under the dashboard. That was the perfect deuce. I made a set of blank flanges for the front axle, and cruising the highway at 55 I could take my foot off the gas on a level stretch and the truck would coast easily along instead of immediately slowing down due to differential drag like a stock deuce. And the rear tires never scuffed when backing up or maneuvering. While off-road in slippery situations with the front axle engaged, a flip of the dashboard switch locked the rear axles together for better traction. Other then the cost, I wonder why the military didn’t opt for such a practical setup.

Show Your Age With Pride

Q: In an article on Parking Brake Service you mention that turning the brake drum to true up the surface is not recommended because the shoe (or band) might not be able to be adjusted properly. Not to show my age, but in my day when this was done they added a shim behind the lining equal to the amount taken off the drum. However, most shops today are probably not familiar with this procedure. —Leonard McCabe

A: If folks like you with experience don’t “show your age”, how will younger people learn anything? Of course you’re right about adding shims to compensate for a parking brake drum being turned, but you are also correct in saying that many repair shops today wouldn’t know that. Thus, it’s important for those with experience to share their knowledge with younger people who may be just now buying a vintage HMV and don’t know the tricks and procedures for keeping an older vehicle in good running condition. Thanks for sharing your valuable experience!

The Strange Case of The Vanishing Oil

Q: I own a 1964 Unimog 404. I was checking the oil levels the other day and found the transmission almost empty. I topped it off three months ago, and there is no oil leaking under the truck. What could have happened to the oil? Is this a leak that only happens when I’m driving? —Luis Gonzales

A: If a Unimog’s transmission output seal leaks, it doesn’t show externally. It leaks down the inside of the drive shaft tube, and overfills the differential.

Send your favorite Tech Tip or question to Steve Turchet at military@aimmedia.com

Looking for more Tech Tips? Here are a few more articles for your reading enjoyment.

From the staff of North America's no. 1 historic military vehicle source -- Military Vehicles Magazine