Unconventional Power: Multifuel engines were made toe come to the rescue in times of crisis

The first production engines were the LDS-427. These engines incorporated the M.A.N. combustion system to allow them to run on a variety of fuels.

During the 1950s, concerned about the potential devastation of the national infrastructure in the event of a nuclear war and the resulting havoc to supply systems, the U.S. military saw a need for tactical vehicles that could run on several different kinds of fuels, such as diesel, kerosene, jet fuel and gasoline. Since cargo and troop-transport vehicles are the backbone of supply, these were to be fitted with the new “multi-fuel” powerplants. Although the Reo Truck Company, which had originally designed and built the famous M35 2½- ton truck (G742 family of vehicles), submitted a design for a multifuel engine, the contract was awarded to Continental, which developed “Hypercycle” engines under license from M.A.N. of Germany (Maschinenfabrik Augsburg-Nürnberg).

The first production engines were the LDS-427. These engines incorporated the M.A.N. combustion system to allow them to run on a variety of fuels. While this multifuel capability was intended to provide strategic support under the worst of tactical conditions by allowing vehicles to operate on whatever fuel sources were available, this capability was seldom actually needed or used.

Although this may seem like an example of simply solving a potential problem — or answering a question that was (thankfully) never asked -— building a reliable engine that would run efficiently on a variety of fuels was a major engineering challenge and involved a lot more than simply modifying existing engine designs. Firstly, diesel engines time the injection of fuel for combustion at just before the beginning of the power stroke. On the compression stroke, the engine is only compressing air. Then, when fuel is injected into the hot pressurized cylinder, it quickly ignites and burns at a stable rate, which instigates and completes the power stroke. Such an engine requires fuel that ignites easily from heat alone, since there are no spark plugs, and diesel fills the bill. There are other fuels that work well in a compression engine, such as kerosene, jet fuel, and various commercial and marine fuel oils, all of which also provide necessary lubrication for fuel and injector pumps.

and a fuel density compensator to provide consistent power output from different fuels.

By contrast, gasoline is a very poor fuel for a conventional diesel engine. In technical terms, it has a longer ignition delay. Since the injection of fuel is timed to a precise point in the compression stroke —- so that ignition occurs at the right time to create the most power to push the piston back down —- with the longer ignition delay of gasoline it would take too long to ignite and create the pressure needed. And/or, the high cylinder heat and pressure might make the more volatile gasoline detonate uncontrollably — explode — damaging the engine rather than burning in the controlled manner of conventional compression engine fuels. In addition, there is the problem of lubricating the fuel pump and injection mechanisms. Diesel fuel pumps have very close tolerances, operate at high pressures and require lubrication from fuel. Gasoline, which provides no lubrication, would quickly destroy the pump, so Continental working with American Bosch, had to design a pump capable of dealing with gasoline, though gasoline was always the least desirable of possible fuels with MIL-G-3056 combat gasoline the worst, and the recommendation that some sort of oil be added — even used motor oil — if possible.

On January 4, 1963, the trade journal Commercial Motor, announced:

“A new U.S. Army truck engine featuring a new combustion principle has been developed by Continental Motors and U.S. Army Ordnance. It uses a variety of fuels and has an interesting fuel injection system, developed and supplied by American Bosch Arma Corporation. Called the Hypercycle LDS-427-2, the engine is now in production at Continental Motors’ Muskegon, Michigan, plant and is the first multi-fuel engine to be delivered to the U.S. Army in production quantities. The engine has undergone extensive testing in the sub-zero temperatures of the Arctic and has also been subjected to the most difficult operating conditions in the high temperatures of the desert. Under these extremes, it has proved capable of operating on any available military fuels, such as petrol, paraffin, diesel fuel, crude oil, and all types of jet fuels. In the Hypercycle combustion system, fuel is sprayed against the wall of a spherically shaped combustion chamber located in the crown of the piston. Through the use of a specially shaped intake port, the induction air is given a swirling motion, which persists in the combustion chamber and continues to supply oxygen to the burning fuel. The swirling air provides the correct mixture for burning at the evaporation surface, resulting in an unusually smooth combustion process. The controlled burning of the fuel prevents accumulation of vaporized fuel so that knocking does not occur, even when operating on low cetane petrol and turbine fuels. This unique combustion development has the advantage of permitting the use of standard automotive materials for all other component parts of the engine. The American Bosch multi-fuel injection system comprises a PSB fuel pump with governor, supply pump, timing unit, spray nozzles and nozzle holders. Its unique design highlights more than twenty-five years’ experience in fuel injection of American Bosch, the U.S.A.’s largest independent manufacturer of injection systems. To develop an injection system of multi-fuel capability, a major problem was the loss of lubrication within the pumping elements when using low viscosity fuels like petrol and paraffin. Design of a dual-action pumping unit solved this problem. The single cam-actuated plunger reciprocates for the pumping action and continuously rotates for fuel distribution to the various cylinders. This dual action permits a closer fit within the barrel, or hydraulic head, and prevents plunger seizure with light fuels. Further redesign resulted in the use of engine oil pressure to lubricate the camshaft, camshaft bearings, tappet and lower portion of the plunger. American Bosch has since incorporated these features in an entire range of fuel injection systems.”

While these engines could run on straight gasoline if there was no other choice, adding some (preferably) diesel would lower the octane rating and speed up the ignition delay, making it at least a bit more suitable. In other words, the farther away from diesel, the worse the engines would run.

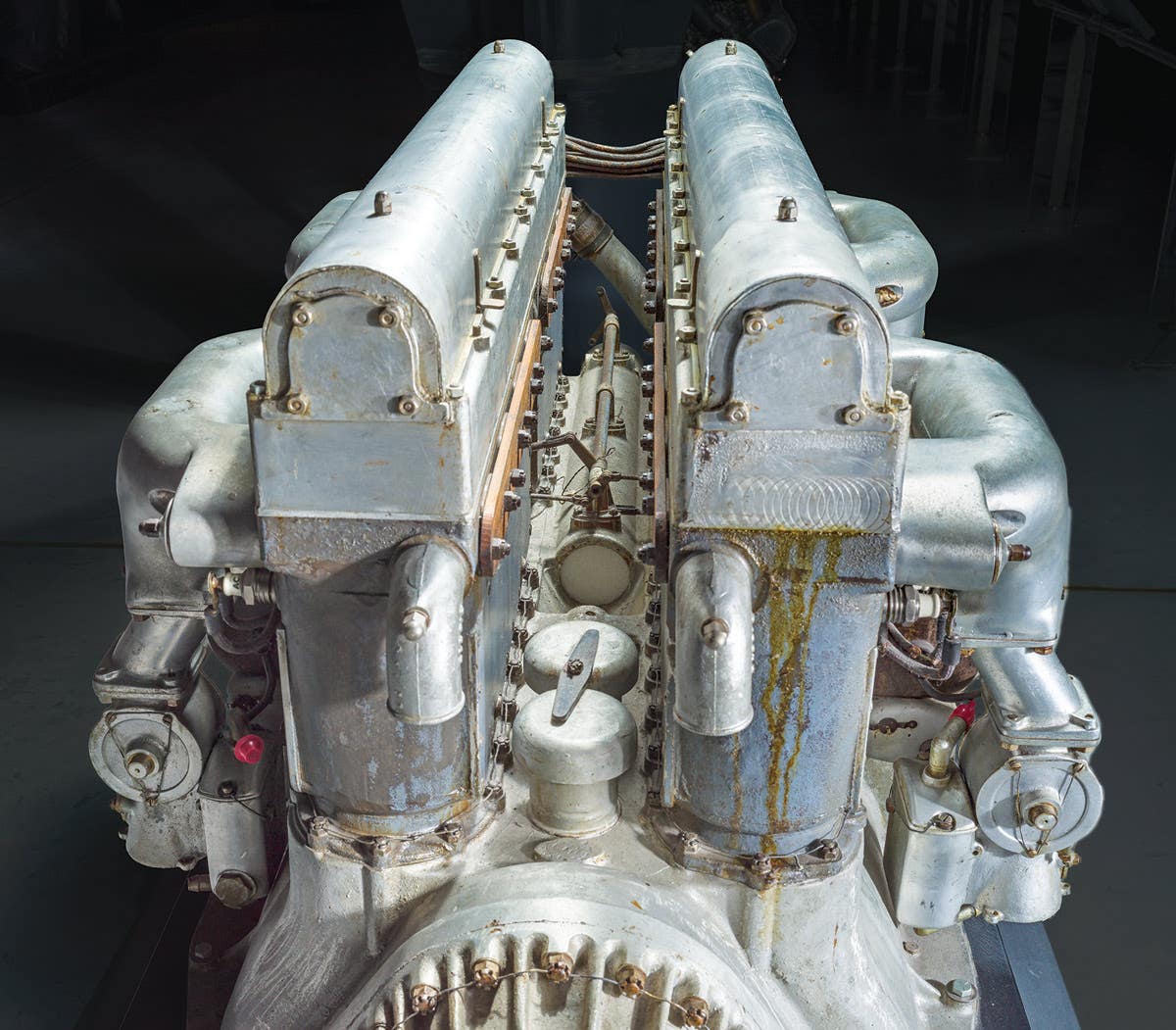

The LD-465 was an evolution of the LDS-427 engine, developed with specific features to support its multifuel capability. The engine incorporated the Hypercycle combustion system, a water-heated intake manifold, a simplified manifold flame heater, and a fuel density compensator to provide consistent power output from different fuels. Like its predecessor it could run on a variety of fuels, including diesel #1 and #2, kerosene, jet fuels, and gasoline mixed with oil. The LD-465 was used in the M35A1 and A2 series of 2½-ton trucks, and the M39 and M54 5-ton cargo trucks and variant vehicles. Multifuel engines were also used in the M656 8x8 amphibious truck. The engine further evolved into the LDT-465, adding a turbocharger (T) primarily to reduce exhaust smoke and aid combustion rather than to appreciably increase power.

It should be remembered that these were mechanically controlled engines from the mid-20th century, and while they could run on a variety of fuels, they sacrificed performance for that ability. The LD-427 had a displacement of 427 cubic inches, or 7.0 liters. It produced 130 net horsepower running on diesel, or a lesser 118 hp on compression ignition fuel compliant with MIL-F-45121. It would achieve just 103 hp on gasoline. Similarly, diesel would produce 330 lbs.-ft. of torque, but that would drop to 280 lbs.-ft. on gasoline.

The later LDS-465 was a larger displacement engine, measuring 478 cubic inches or 7.8 liters. It had an output of 170 to 185 hp, and a maximum torque output of 440 lbs.-ft. of torque. It had a fuel density compensator to meter different amounts of fuel to the engine based on the density of that fuel, although the “FDC” was a somewhat troublesome component and was often bypassed, and the vehicles were usually run on diesel fuel only.

The same concept applied to many NATO combat vehicles, which run on JP-8 fuel. This fuel was introduced in the 1980s as the Single Fuel Concept; and JP-8 is close enough to diesel that it works well in conventional diesel engines while also being suitable as a jet fuel.

While multifuel engines may have kept supply lines open and men and equipment moving under the worst of tactical conditions, that, as gratefully noted, never came to pass and the multifuel concept faded into history, with many current U.S. military vehicles powered by conventional commercial diesel engines. With a few exceptions, multifuel engines were seldom needed in civilian applications, and those still in use are mostly in the caring hands of military vehicle collectors and enthusiasts.