Historic Military Vehicle Ignition Systems Part II

by Steve Turchet Trouble shooting and tune-up Part One of this article (MVM, no. 184, October 2016) covered the operating principles of internal combustion engines and the various components of…

by Steve Turchet

Trouble shooting and tune-up

Part One of this article (MVM, no. 184, October 2016) covered the operating principles of internal combustion engines and the various components of their ignition systems, both magneto and battery. Since most common collectible U.S. historic military vehicles (HMVs) have battery ignition systems, we’ll now learn some trouble-shooting hints and tune-up procedures for these. For detailed tune-up procedures on your own vehicle, it’s always best to buy a manual.

As we learned in Part One, the distributor is the heart of a battery ignition system. We also learned there isn’t a lot of difference between the civilian-style 6- or 12-volt systems of most WWII vintage U.S. military vehicles and the 24-volt waterproof systems used on most M-series MVs from the early 1950s into the 1980s – except that troubleshooting and repair is a little harder to do on waterproof systems.

Keep in mind (especially if you’ve just acquired your HMV), it’s very common to find that your vehicle’s ignition system was modified by a previous owner and may not have its stock-type distributor and/or other components. Over the years, I’ve received lot of letters from folks who just bought their first M37 or M38 and ordered tune-up parts that “didn’t fit.” The reason these parts didn’t fit was because the vehicle had been modified with a 12-volt civilian ignition system, and the new owners didn’t know what a 24-volt waterproof system looked like. Ignition parts are often sold on a non-returnable basis, and these kinds of mistakes can be avoided if you will buy a manual for your specific HMV so you know for sure what all of its stock components look like.

I wish I had a dollar for all the ads I’ve seen – including in this magazine – for “Army jeeps” or “Army trucks” touted as being “totally stock” or “fully restored” but were actually far from it. This usually isn’t deliberate deception on the part of the seller, because they didn’t know either. So, don’t assume that the spark plugs (for example) that were in your HMV when you bought it are necessarily the ones it should have.

Always know your distributor’s manufacturer (Autolite, Prestolite, Delco-Remy, Holley, etc.) and its number when ordering parts. That number is usually on a little plate or tag riveted to the distributor’s body, though you may find, as with similar plates on starters and generators, it’s missing.

In Part One we learned that distributors are usually driven from the engine’s camshaft and rotate at half engine speed. They perform four basic functions: 1. They use breaker points to create a high voltage spark – around 15,000 to 20,000 volts – from the coil to fire the spark plugs; 2. They direct this spark to the proper spark plug in the correct firing order and at the right time, via the rotor and distributor cap; 3. They adjust the timing – when the spark plugs fire – to best suit the engine’s RPMs, via the centrifugal advance mechanism; and 4. They adjust the timing to better suit the engine’s load, via the vacuum advance mechanism.

We also learned that most waterproof M-series distributors don’t have this fourth feature, which makes the 230 engine in your M37 or the 134 engine in your M38A1 slightly less efficient then the same 230 engine in a Dodge civilian truck or the 134 in a CJ3B or CJ5. I don’t know why the military decided to leave out the vacuum advance, but the loss of efficiency isn’t that big of a deal. Most cars and trucks up until the late 1930s got along fine without a vacuum advance.

The illustration at the left shows all the components of a pre M-series ignition system. This is the system used on virtually all WWII U.S. military vehicles, such as MBs, GPWs, GTBs, WCs, G-506s, CCKWs, DUKWs, etc., including most heavy trucks and special vehicles of that period... Studebaker, I.H.C., the Weasel and so forth (though some tanks and amphibians had magneto systems). Most of the time the only difference between WWII military systems and their civilian counterparts is the military versions sometimes have “splash-proof” distributors. The splash-proofing is generally just a Bakelite shield that fits into the distributor underneath the rotor and protects the points and condenser from... well, splashes.

If you guessed that this item was frequently lost by a later civilian owner, you guessed right. If you’re buying an NOS (New Old Stock) or rebuilt HMV distributor, always ask if this shield is included. Your vehicle will run fine without it, but if you’re doing a complete restoration you’ll probably want it.

Since most WWII and pre M-series systems were basically off-the-shelf civilian, locating their parts shouldn’t be any harder than finding parts for any civilian car or truck of similar vintage. Besides splash shields, there are a few other special military components, such as the armored coil wire that came on many half-ton WWII Dodges. However, Dodge also used this setup ,on some of their civilian vehicles... check the Dodge and Power Wagon ads in this magazine, or give the Internet a try.

If you use your HMV as a daily driver – and especially if you take it into the bush – you should always carry a complete set of extra ignition parts: Points, condenser, rotor, cap, and coil. You should also carry the basic tool kit and emergency items which will enable you to troubleshoot your ignition system problems in the field and install your new parts if necessary. One of the most frustrating situations to be in is when your vehicle breaks down and you don’t have the tools you need to fix it.

Having a spare complete distributor ready to install is neither expensive (if you do a little shopping around) nor space consuming; and you’ll often find in emergency situations that it’s simpler and faster to install your spare distributor rather than take the time to find out what’s wrong with the one on your engine. In many cases, you can install a complete distributor in less time than it takes to replace a set of points and condenser.

Used components can be just as good as new ones to carry with you, though it’s safer if your spare coil is new. All the above goes double if you have an HMV with a 24-volt system. If so, you should also carry a complete set of spark plugs and at least one of the longest spark plug wires if you’re venturing far from home.

There is a third type of ignition system you may occasionally encounter in your HMV experience. These are generally found on vehicles, such as M37s, M38s and A1s, M715s, M211s and early gas-powered M35s, that were previously owned by fire departments or municipalities (though individual owners will sometimes build one of these). This is where someone has morphed a 24-volt distributor into a 12-volt system.

This is usually accomplished by adding a 12-volt external coil and a few extra bits of wiring. If done properly, these work fine, and there may come a time in an emergency situation where you might want to build one yourself, but of course they are not “correct.” You may find such modified systems on many HMVs advertised as being “totally stock” or “fully restored.”

If you want to convert your 24-volt HMV to a 12-volt system, it would be better to find a 12-volt distributor. This is usually no problem for M38s, M38A1s, M37s, M715s, or GMC and Reo deuces.

There isn’t much practical purpose in making a 12-volt conversion and retaining your 24 volt distributor unless you actually need a truly waterproof ignition system. I once installed a 24-volt distributor from a GMC M211, complete with wires and spark plugs, on a 1963 Toyota Landcruiser FJ-45 and converted the distributor to 12-volts. Why? Because I thought it looked cool, and I had the parts and time to play. But if you only want a 12-volt system, then why would you want the 24-volt distributor with its relatively hard to find parts? Better to just make a complete conversion with all civilian components. Plus you will get a vacuum advance.

TUNE-UP

As with many mechanical terms, “tune-up,” “basic tune-up,” or “complete tune-up” often mean different things to different people. For the sake of clarity, we’ll only talk about an ignition system tune-up in this piece, as opposed to one that includes carburetor work... although a carburetor adjustment is often required after an ignition tune-up, especially if your vehicle needed a tune-up to begin with. Why? Because we tend to compensate for a misfiring ignition system (at least at engine idle) by making the fuel mixture richer.

To a lot of home mechanics a “tune-up” can mean something as simple as cleaning the spark plugs and filing and resetting the points... and many times this is all that is needed. My own definition of a “basic tune-up” means replacing the points and condenser along with cleaning and re-gapping the spark plugs. My definition of a “complete (ignition) tune-up” means replacing the points and condenser along with the rotor and cap, as well as installing new spark plugs.

Of course, this is only a generalization to give you some idea what’s involved. For example, you might want to do a “complete tune-up” but you find that your old rotor and cap are perfect, and/or that your spark plugs are still in good shape. No problem: just put in the new parts anyhow and save the good used ones as spares. You’ve lost nothing, plus you’ve gained spare parts.

A complete (ignition) tune-up may also be a good time to replace your spark plug wires. These wires age, their insulation cracks, and they eventually fail; and engine misfire, uneven idle, and hard starting, especially on foggy or rainy days, is often caused by aged or cracked spark plug wires. You should keep your wires clean because a coating of dirt or grease can make them leak current, which cuts down the voltage to the spark plugs. Wiping them with a rag soaked in WD-40 not only keeps them clean but also helps to preserve them. Be sure to use a little dielectric grease around where their terminals connect to the distributor cap and the spark plugs. This will stop the brass or copper from corroding and also tends to keep out moisture. Plus it makes it easier to take the wires off again a few months down the road.

How often should you do a tune-up (complete or otherwise)? That’s hard to generalize for HMVs, unless yours is a daily driver... in which case you should follow the advice of your manual. But most HMVs aren’t daily-drivers; and mileage recommendations become meaningless for vehicles that are used only on weekends, in the summertime, or for parades, etc.

For most of these vehicles, common sense and the way your vehicle behaves should be your best guide to tune-up intervals. For example, if your MB is getting increasingly hard to start, your M37 begins dying at every stoplight, or your Eager Beaver becomes a reluctant rat, these are good indicators that a partial or complete tune-up is in order. In these examples, the most likely problem is dirty or fouled spark plugs and/or dirty points, burned points, and/or points that need adjusting.

Adjusting points? Yes. The rubbing block – the part on the points assembly that rubs against the cam to open and close the points – is always gradually wearing down, which narrows the gap (how far the points open on the lobes of the cam). Keeping the cam clean and polished, along with a tiny bit of cam-lube grease, will greatly prolong the life of the rubbing block and therefore maintain the correct point gap.

It’s common for the cam to get rusty on vehicles that aren’t driven a lot, and of course this wears the rubbing block faster. The point gap (how far the points open) controls the amount of time the ignition coil has to build up a charge to fire each spark plug. The point gap also controls engine timing to a minor degree – how far the points open “decides” the instant at which the coil fires its charge to the spark plug – so maintaining the correct gap is essential for efficient operation.

Hard starting and rough idle can often be traced to points with too narrow a gap, usually caused by a worn rubbing block... assuming the points were correctly set when they were installed. If you ever encounter a situation where your vehicle will only run with the choke pulled out halfway, one thing to check is the point gap.

NEVER leave your vehicle’s ignition switch on when the engine isn’t running! Doing so can burn the points, burn out the condenser, and may also burn out, or even burst, the coil. Most standard ignition coils are filled with oil for cooling, and besides making a mess if they burst, they will leave a nasty stink in your vehicle for a long time afterward.

In Part One, we mentioned how even the best cleaned plugs will usually get dirty again faster than new ones (though this shouldn’t keep you from cleaning them anyway) and “hotter plugs” are usually your best choice for short distance stop-and-go driving, while “colder plugs” are a better choice for long-distance high-speed travel.

Remember, “hot” and “cold” has nothing to do with the intensity of the spark, but refers to how hot or cold the plug itself becomes during operation. Finding the best spark plug heat range is no problem for owners of pre M-series vehicles, but the choice is limited for M-series vehicles. Still, I’ve always had better luck with Autolite or Motorcraft waterproof plugs than with Champions.

TUNING TIME: THE PLUGS

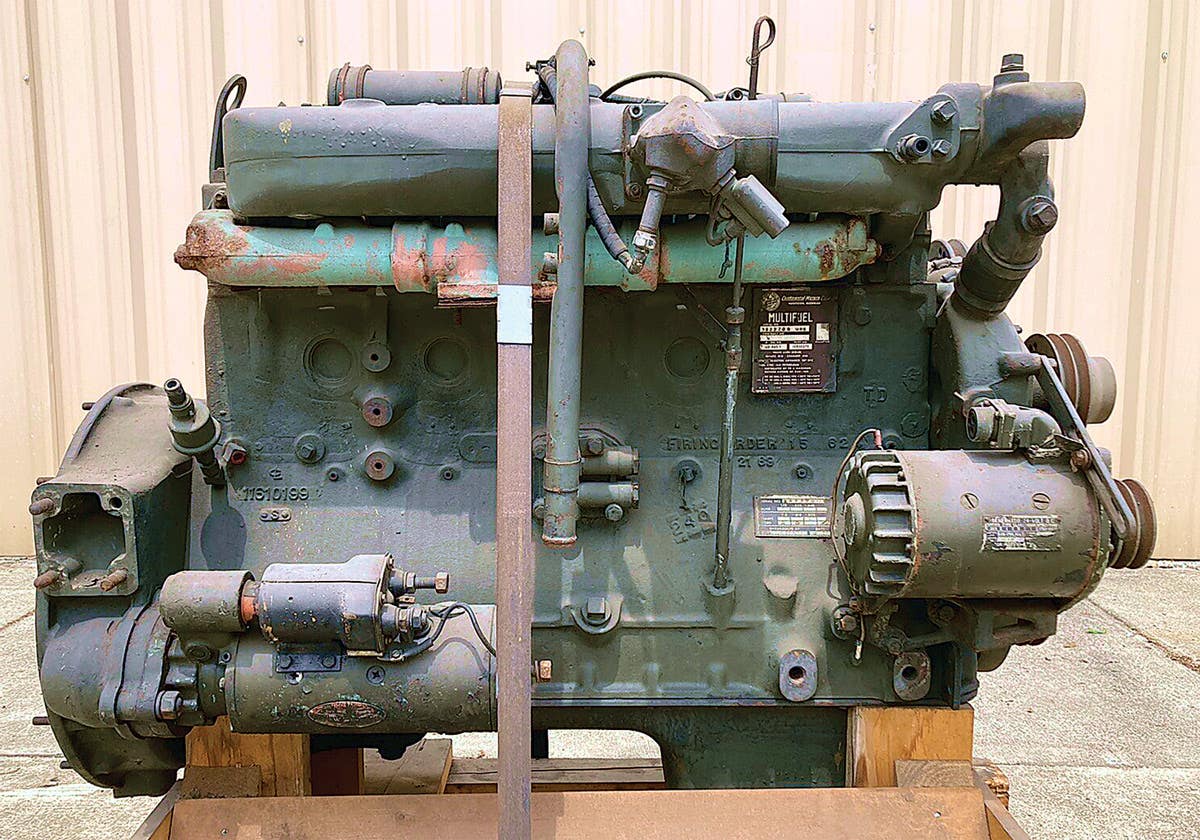

If you have the basic tool set I’ve recommended, then you should have everything you need to do a tune-up on your HMV, so let’s do a complete ignition tune-up on two of the most common collectible military vehicles: a Dodge WC and a Dodge M37. Why these two? Because they have the same engine but the WC has a civilian styleignition system while the M37 is 24- volt, waterproof system. If you prefer, you can pretend these vehicles are a Willys MB and a Willys M38 – same concept.

What about ignition timing? Do you need to re-time your engine after a tune-up, and do you need a timing light to do it? Technically yes: however, as with most of my articles I’m writing for the “average HMV owner,” and many competent home mechanics don’t have timing lights.

Speaking as a bush mechanic, I seldom use a timing light simply because I’ve found that timing by ear and engine performance usually works better. I’ve also seen a lot of situations with older engines where timing them with a light to factory specs actually made them run worse instead of better. (By the way, many M38A1s left the factory back in the 1950s with incorrect timing marks.) But if you have a timing light, by all means use it.

Unlike changing the oil, you don’t want your engine warmed up for this job or you’ll probably be burning yourself on the hot engine and spark plugs. However, I do like to run the engine a few minutes before I begin. The main reason is because it’s good to be able to compare how well (or not) it was running before I tuned it up.

I’ve known people who have tuned up a vehicle that hadn’t been started in a year, and when it wouldn’t start they had to try to figure out if it was something they just did that caused the problem... or was it something that had gone wrong while the vehicle was sitting?

It doesn’t really matter, but I usually install new spark plugs first before working on the distributor.Since the engines in this example are L-heads (or flatheads) with their spark plugs set in wells, it’s a good idea to blow or otherwise clean the dirt, sand, or caked grease out of these wells before removing the plugs so that nothing falls down inside the cylinder.

I like to remove and replace one spark plug at a time. Why? Because each plug tells a story about the condition of its cylinder and how well it’s been running.

For example, if five plugs come out of a six-cylinder engine sort of reddish brown and dry, but the sixth is black and wet, it generally means that plug has been misfiring. This could possibly be due to a bad spark plug wire, or a wire with a loose terminal at either the spark plug or distributor cap end; or it could indicate more serious trouble like a leaking head gasket or even a broken piston or piston ring.

If two adjacent spark plugs come out dirty while the other four are clean, it usually indicates a leaking head gasket between the two cylinders (fairly common on Dodge 230s).

At the very least, you will probably find that the plugs at the front of your engine are a little dirtier than the others. Why? Because the engine runs cooler at the front. That’s where the cooled water comes back from the radiator. Generally speaking, the hottest cylinders on most in-line six-cylinder engines are 4 and 5.

Check to make sure there aren’t one or two “extra” spark plug gaskets stuck on the cylinder head. I’ve seen engines with as many as three or four of these gaskets almost fused to the head. And make sure the plug you just removed has a gasket that’s accounted for. Technically, you should replace these gaskets every time you remove the spark plugs, even if you’re just cleaning and reinstalling them, but I’ve never known anyone who did. Just make sure you use the new gaskets on your new plugs.

The best way to clean your spark plugs is with one of those little sandblasting kits THAT are available at most good auto and truck supply houses or may be ordered off the Web. These consist of a little canvas pouch and chamber that you fill with a special grit and hook to your air compressor. There has been controversy in the past about cleaning spark plugs this way – a few sloppy mechanics weren’t getting all the sand off the plugs before installing them, so the sand went into the engine – but blowing the plug clean with few blasts of air will prevent this. It’s easy to overdo this sandblasting. You just want your plugs clean, not eroded like the Sphinx.

Another way to clean your spark plugs is with a wire wheel, but then you’ll have to use something like an ice pick to gently dig out the carbon and combustion deposits from around the center electrode. Naturally, you’ll be careful not to chip or crack the porcelain. Hand wire brushing is just as effective but of course will take longer. Then, fold a bit of emery cloth or fine sandpaper and draw it between the center electrode and the grounding electrode a few times to clean the spark gap.

For at least 80 years most repair manuals have recommended using a round gauge to reset the spark plug gap – and most people (including myself) use flat ones. The choice is yours.

Don’t forget to clean the top of the plug, because dirt or caked-on grease can cause the plug to misfire. Also make sure the screw threads are clean. If your engine is an oil-burner and your plugs are black and sticky, the only real solution is to rebuild the engine. You can try hotter plugs, or even “anti-fouler” devices, but you’re only delaying the inevitable, and you’ll be cleaning your spark plugs a lot.

If you have a 24-volt vehicle, be careful when removing the spark plug wires from the plugs and the distributor terminals. If they’re stuck inside, use something like WD-40 and a lot of care, or you’ll break off the terminals and/or the porcelain insulators.

Use dielectric grease when you reinstall them so they don’t stick again. Even civilian-style wires will sometimes stick to the plugs or in the distributor cap... don’t pull on the wire or you may break it off the terminal. Care and WD-40 will pay off here, too. Use dielectric grease when re-attaching these, as well. If you have a 24-volt system, use the grease on the terminal nuts, too, and be careful you don’t cross-thread them. This is easy to do on the plug ends.

NEXT STEP: THE DISTRIBUTOR

We’ll assume that by now you’ve either cleaned and reinstalled your old plugs or put in new ones (always check the gap on new plugs), so we’ll move on to the distributor.

The caps of most civilian type (pre M-series) distributors are usually held on by two spring clips. Remove the cap and examine the inside. If the terminals and center carbon aren’t badly burned or eroded, you may want to use the cap again or keep it for a spare.

If the cap looks okay, there’s no need to disconnect the spark plug wires, unless you want to take it off and clean it. If you do take it off, mark or tag the plug wires so you can put them all back in the right order and on the correct terminals. Do this marking carefully! It’s very frustrating to have done the perfect tune-up and then have your engine blast and backfire when you try to start it because you got the spark plug wires crossed or out of order.

If you’re going to clean the cap, any reference marks you made might be washed off, so you may want to use an ice pick or a nail to mark it. Some manuals advise not to try to clean the cap’s electrodes because it may widen the gap between them and the tip of the rotor, but lightly polishing them with crocus cloth is okay. The same goes for cleaning the rotor. If the cap and/or rotor are badly burned or eroded, it’s best to replace them, even if the engine seemed to be running all right.

As with the spark plugs, dirt or grease on the outside of the cap may cause hard starting or misfires, so wash the cap with your solvent of choice. Look for any cracks or signs of carbon runners inside the cap. If a carbon runner develops, what happens is no matter where the rotor is pointing, only the spark plug with the runner will fire – which makes a lot of noise but won’t get you anywhere. If there is any sign of a runner beginning to form or a crack (in which one will probably form), discard the cap. You can clean off a carbon runner, but it will usually form again.

On 24-volt distributors, the cap is inside a steel shell, but examination and service is the same. Be careful when reinstalling these caps. Tighten the screws evenly, but lightly, because the cap is easy to break.

After you’ve taken care of the cap and rotor, remove the points and condenser from the distributor. Youyou should have the correct screwdriver, tiny wrenches, and/or miniature groove-joint pliers to do it with. Another handy tool is one of those little screw-holders/starters with a magnet on one end – doubly handy if a screw falls down inside the distributor body – and even more useful when reinstalling the parts.

Depending upon your engine and vehicle type, it may be easier to remove the distributor to work on it. If you do, be sure to reference mark it carefully so you can reinstall it without messing up the timing.

Examine the points: if the contacts are badly pitted, burned or eroded and/or the rubbing block is just about gone, they should be discarded. If the rubbing block is in good shape and the contacts aren’t badly burned or worn, you can dress the contacts with a points file. You can also use crocus cloth or fine sandpaper, but try to keep the faces of the contacts square with each other.

We learned about condensers in Part One. It’s possible for a condenser to outlast several sets of points; and though in theory condensers should be tested and only replaced if they fail, most of us don’t have a tester, and it’s a good idea to replace them every time you replace the points and keep the old ones for spares.

A warning about condensers: since breaker point ignition systems were mostly phased out in the 1980s, many condensers sold by auto part stores these days are of very poor quality and/or may be of the wrong value for your particular engine. Only buy quality condensers from businesses you trust.

It’s true that the same condenser may be used in many different vehicles, but there are no “universal” or “one-size-fits-all” condensers. If someone tries to talk you into buying such an amazing item, don’t.

While it’s pretty hard to make a condenser look “cheap,” I’ve seen a few that do; and ifit does look cheap, don’t buy it. Again, a quality condenser should last for years, but a “cheap” one (as I found) may only last a few weeks.

Many 24-volt distributors also have a coil capacitor and a resistor. The coil capacitor is usually quite long-lived, but you should always have a spare on-board. The resistor should outlast your vehicle but, again, having a spare is a smart idea. And always carry a new spare 24-volt coil if you use your HMV a lot.

Now clean the inside of your distributor with a lint-free rag. Starting fluid or brake cleaner sprayed into the distributor does a wonderful job of cleaning above the breaker plate. Unfortunately, it also blows dirt and grease under the breaker plate and down inside the distributor body, so don’t do this.

On 24-volt distributors, check that all the nuts and screws – coil wires, resistor, capacitor, etc. – are tight. But remember these are little fasteners so don’t over-tighten and break them.

Examine the cam to be sure it isn’t rusty. If it is, it will wear down the rubbing block. If necessary, polish it with fine crocus cloth, but be sure to get all the grit out after polishing.

After everything is clean, install the new (or good used) points and condenser. Set the points to the correct gap (read your manual) by bringing a lobe of the cam around until it fully opens the points and the rubbing block is on the highest part. I generally turn the engine by hand (with the transmission in neutral, of course) using the fan. On some engines you can also use a stout screwdriver inserted through the timing hole in the bell-housing to lever the flywheel around.

As with spark plugs, most manuals recommend using a round feeler gauge to set the points... but most people use flat ones. With the correct gap, you should feel a slight drag when drawing the blade of your gauge between the open contacts. This is one of those times where experience helps (how “slight” is slight?) but the gauge blade should slip between the contacts without forcing them any farther apart. This isn’t a scientifically precise adjustment, though it should be as close as you can get it. If in doubt, it’s better to set the points a bit too wide than too narrow because the rubbing block will always wear down. If you have to make a field repair and don’t have a feeler gauge (why not?) then a paper match book cover is close to .020 of an inch... a setting at which most common HMVs will run.

After the points are set and tightened down, check the gap again. You will often find that it closed up a bit more after the points were tightened. If so, be patient and go through the process again. You may find that you need to set your points a bit wide because they will often close up slightly more when you tighten them down.

As with the other little fasteners, don’t over-tighten the point screws. Smear a small amount of cam lube around the cam’s rubbing surface. Don’t use wheel bearing or chassis grease because a distributor gets hot during operation and such greases may vaporize and foul the point contacts. And never use graphite grease because it conducts electricity and may cause the distributor to misfire.

Now install the rotor and cap. (You would not be the first person in the world to forget to install the rotor). If there is an oil wick (felt) on top of the distributor shaft (under the rotor) put one or two drops of engine oil on it. Likewise, if the distributor has an oil cup or grease fitting, fill or lube it. Since you marked all your spark plug wires (didn’t you?) it will be no problem getting them all back on the correct terminals and in the right firing order. (As with the rotor, you would not be the first person in the world to forget to install the coil wire.)

Now start the engine. Sounds good?

Let the engine warm up, and you may find you need to lean out the carburetor idle mixture a bit. Why? Because your engine is probably firing better now so it needs a bit less gas to run.

As I mentioned before, it’s not entirely essential that you mess with the timing when doing a tune-up like this, but if you want to be adventurous you can loosen the distributor mount and slowly turn the distributor to find the best sounding idle. If you do this, it’s a good idea to mark the distributor’s original position before you move it.

Don’t be afraid to experiment... rotate the distributor little by little both ways until you can hear for yourself what an engine sounds like when its timing is either too advanced or too retarded, and how smooth it sounds in between. On most civilian style distributors, the vacuum advance points in the direction of shaft rotation, so turning the distributor toward the vacuum advance advances the timing, while turning it away retards the timing.

When you’re satisfied with the idle and the engine is warm, rev the engine a few times to see if there’s any hesitation off idle. If so, you may want to mess with the timing until there’s no stumble spot... though stumble spots are more often caused by carburetor problems. Then take your vehicle for a drive.

If the timing is too retarded you’ll notice a lack of power and probably some hesitation when accelerating. On the other hand, if the timing is too far advanced you will hear raps and rattles on hard acceleration or when climbing a hill... don’t let this go on very long!

In either case, simply pull over and readjust the distributor. Chances are excellent that when you’re satisfied with how your vehicle sounds and performs, you’ve gotten its timing just about right.

And that’s about all there is to ignition system basics.