Jumpy jeep, hard braking, fuel pump calibration, cracks and more in this installment of Tech Tips

Something not right with your historic military vehicle? Steve Turchet answers your questions on how to keep ’em movin’!

Jumpy Jeep

Q: I own a 1952 Willys M38. I have always found your tech tips to be helpful in repairing it. The transfer case jumps out of gear in 4-wheel drive. Can you suggest what might be causing this problem and how to fix it? Do I have to take out the whole transmission and transfer case just to work on the transfer case? — Bill Holden

A: I’m glad to hear my tips have been helpful! Thank you for reading and taking the time to write. The most probable causes of your jeep slipping out of front wheel drive could be a weak shifting fork lock spring, a badly worn front bearing, too much end play in the drive shaft, and/or a bent shift fork. The latter is often caused by trying to force the shift lever in or out of gear. You can remove the transfer case from your M38 without taking out the transmission. Having the proper manual would be handy, but here’s the short-form: Drain the transmission and transfer case oil. Then, disconnect the parking brake linkage followed by the front and rear drive shafts and the speedometer cable. Then disconnect and remove the transfer case shift levers. Remove the round cover plate from the rear of the transfer case, then remove the cotter key (if used), then the large nut and washer from the transmission main shaft. Then remove the transfer case drive gear from the transmission shaft. Remove the transfer case mounting bracket (right side). It will be helpful to have a transmission jack for the last step. Remove the transmission-to-transfer case bolts and the transfer case will be in your hands. After you’ve found and fixed the problem, follow these steps in reverse to reinstall the case. Use plenty of torque on the dive gear nut. I suggest either using a new transmission-to-transfer case gasket, which may be obtained from one of the companies that advertise in this magazine, and old-school; Permatex gasket sealant, either original or High-Tack, rather than relying on silicone sealant.

A Little Pull

Q: Thank you for all the great articles and tips. They are the first things I read when I get the new magazines. Many of the tips have been useful to me. I have noticed a few tips about WWII jeeps pulling to the left on hard braking. I understand this is normal and my own 1943 Willys does it too and I live with it. In your replies to these questions, you say this happens because the steering bell crank on these jeeps is on the. front axle and not on the frame like later model Jeeps. Why does this make old jeeps pull left on hard braking? — Jim Moss

A: Thank you for your kind words about my writing, and I’m glad that you’ve found a few things useful. As to your question: because vehicles nose-down on braking, the front springs compress. This lessens the distance between the vehicle’s axle and frame. Since the steering box is mounted on the frame, with a drag link between it and the bell crank on the axle, something has to give, so the drag link is pushed or pulled against the steering box’s Pittman arm, which turns the steering gear slightly. In the case of WWII jeeps, this causes the front wheels to turn a bit to the left. Unless one has other problems, such as oil or grease on the brake shoes, this pull is usually minor and, like you, the driver learns to anticipate it.

Less Than Perfect

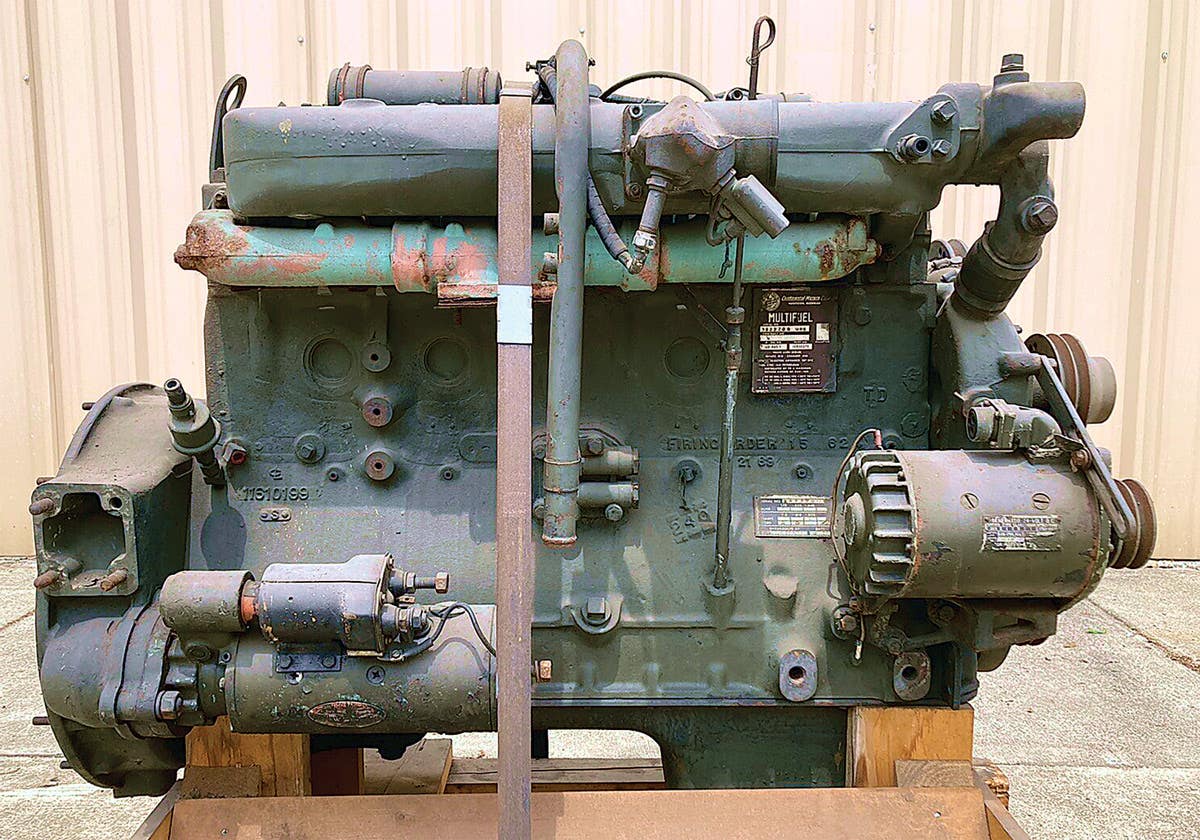

Many HMMWV’s, whether civilian-owned or in military service, don’t have the right fuel-injection pump installed, and/or the fuel-rate calibration is incorrect. This results in either over-fueling, which wastes fuel, produces black smoke, and is detrimental to proper engine lubrication, or under-fueling, which results in lack of power. Proper fuel delivery, either with the correct pump and/or the right calibration, is determined by the amount of equipment loaded onto the vehicle, and/or the type of variant. Installing the correct pump with the proper calibration is especially important for HMV hobby HMMWV owners, who often reconfigure a vehicle.

Simply put, if one lightens an HMMWV whose fuel pump was calibrated for heavy weight, one is wasting fuel. Likewise, if one adds significant weight to an HMMWV without re-calibrating the pump, the vehicle’s performance may be degraded.

Crack Up

Is your HMMWV’s hood cracked or developing cracks? If so then consider the HMMWV Hood Reinforcement kit (NSN 2510-01-547-7220). This kit stops cracks from developing and keeps existing cracks from spreading. The kit is approved for use on all basic, -Al, and -A2 model M998s, as well as M1121s and M1123s. It’s easy to install, and instructions come with the package.

Every Which Way But Loose

HMMWVs seem to be plagued by loose nuts, bolts, and components. One such component prone to loosening is the starter. It’s hard to tell if a starter is coming loose just by looking at it. The best thing to do is get under the vehicle and push up on the starter. If it moves, it’s loose, so tighten it. A loose alternator mount is another common occurrence, and like a loose starter it’s hard to tell with only a visual inspection. Grab the belts — top and bottom — push and pull, and watch for any movement of the alternator or bracket. If you see anything more than a tiny amount of movement, the mounting bolts are loose.

Send your favorite Tech Tip or question to Steve Turchet at military@aimmedia.com

Looking for more Tech Tips? Here are a few more for your reading enjoyment.

From the staff of North America's no. 1 historic military vehicle source -- Military Vehicles Magazine