Eliminating Cosmoline with Dry Ice

by John Schroeder, Owner, Green Clean Dry Ice Blasting, LLC, Lake Mills, Wisconsin Cosmoline is the brown wax-like petroleum-based rust inhibitor used to keep metal from rusting over time. For…

by John Schroeder, Owner, Green Clean Dry Ice Blasting, LLC, Lake Mills, Wisconsin

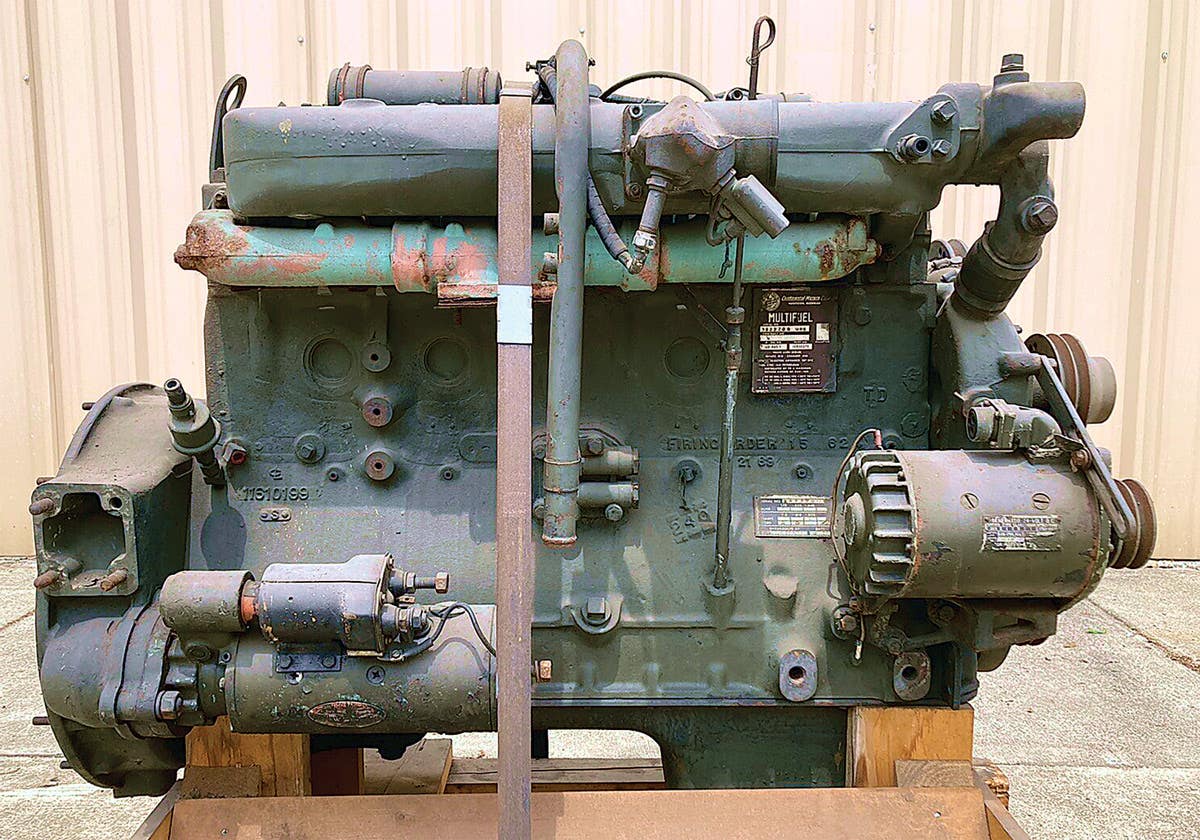

Cosmoline is the brown wax-like petroleum-based rust inhibitor used to keep metal from rusting over time. For those who restore antique military vehicles or collect vintage firearms, you have probably already cursed cosmoline, having cleaned more than your share of it over the years. Cosmoline is usually viscous when freshly applied and solidifies over time with exposure to air. The hardened substance is challenging to remove when the time comes to re-expose the metal.

Having to deal with cosmoline is a mixed blessing. On the positive side, you have a new old stock (NOS) part for your vintage military vehicle or an old firearm that is in like new condition. On the negative side, cleaning cosmoline is a dirty job often involving harsh chemicals, lots of elbow grease, and a lot of clean-up.

There are numerous methods for cleaning cosmoline, including harsh chemicals like gasoline, paint thinner, mineral spirits or other petroleum-based solvents. Non-chemical solutions often include hot water or steam-cleaning. In all these procedures, the biggest issue is the large amount of waste material created while removing the cosmoline.

Another innovative way to remove cosmoline is through the use of dry ice blasting. Dry ice blasting is similar to sand blasting, plastic bead blasting, or soda blasting where media is accelerated in a pressurized air stream to impact a surface to be cleaned or prepared. However, instead of using hard abrasive media to grind on a surface (and thereby damaging it), dry ice blasting uses soft dry ice, accelerated at supersonic speeds, and creates mini-explosions on the surface that lift the undesirable material — in this case, cosmoline — off the underlying substrate.

Dry ice blasting is an environmentally friendly way to effectively and efficiently clean utilizing CO2 pellets propelled at high speed. One of the biggest advantages of using dry ice pellets to clean cosmoline is that there is no secondary waste stream. Unlike sand, plastic or soda, the dry ice pellet sublimates from a solid to a gas upon impact with the metal.

On the Mohs Scale of Hardness, with talc being a 1 and diamonds being a 10, dry ice is about a 1.5. The force of the dry ice’s impact on the surface cleans the item to be cleaned, instead of the hardness of a material, such as sand, which uses abrasion to clean.

When the dry ice (at -109 degrees Fahrenheit) hits the surface and the cosmoline, it creates a micro-thermal shock wave that breaks the bond between the cosmoline and your metal part. The cosmoline then cracks, delaminates, and falls off your part or firearm. When the dry ice pellets hit the metal surface, they explode and instantly convert to harmless CO2 gas. The gas then penetrates any spaces between the surface and the cosmoline, in effect pushing the contaminants off the surface from behind.

Dry ice blasting is not inexpensive, but the advantages in removing cosmoline without the fear of damaging the part’s metal surface and without the secondary waste stream make it a viable alternative to harsh chemicals and messy manual cleaning processes. To find a local dry ice contract cleaner visit: www.dryicecleaning.com.

John Adams-Graf ("JAG" to most) is the editor of Military Trader and Military Vehicles Magazine. He has been a military collector for his entire life. The son of a WWII veteran, his writings carry many lessons from the Greatest Generation. JAG has authored several books, including multiple editions of Warman's WWII Collectibles, Civil War Collectibles, and the Standard Catalog of Civil War Firearms. He is a passionate shooter, wood-splitter, kayaker, and WWI AEF Tank Corps collector.