The M561 Gama Goat: A post-apocalyptic flop

The history behind the ‘quirky’ M561 Gama Goat. A vehicle intended for a nuclear-threatened world.

Hardly had a battered world emerged from the devastation of World War II and the accompanying horrors of the Holocaust in Germany, and Japan’s inhuman treatment of the populations it had invaded as well as to prisoners of war, cumulating with the dropping of atomic bombs by the U.S.A. on the Japanese cities of Hiroshima and Nakasaki, then it was plunged into a new kind of conflict, termed The Cold War, with the Soviet Union and Communist China threatening “the West.” This threat grew all the more ominous when the Soviet Union developed its own atomic bomb in 1949. From then on an arms race began between the East and West in which the atomic bomb evolved into the even more destructive hydrogen bomb, and “atomic cannon” capable of firing nuclear projectiles transformed into rocket-powered missiles which could deliver nuclear warheads across oceans and continents.

It became apparent to Western powers that not only was a global nuclear war possible, but it also seemed all-too probable. A war of this scale would not only decimate civilian populations and leave those not dying from radiation poisoning without food and clean water, but would also ravage a country’s infrastructure, destroying railroads, highways and bridges and leaving a wasteland of rubble. With this threat in mind, the U.S. Military began drawing up plans for a new fleet of cargo and troop transport vehicles to replace those that had served during WWII. This fleet would not only be much more standardized with many interchangeable components, but would also be equipped with waterproof 24-volt electrical and ignition systems shielded to withstand the EMP effect of a nuclear attack. The new vehicles would be capable of fording deep water, with several amphibious types proposed. Engines capable of operating on several different kinds of fuel were also deemed desirable. These new vehicles were what is commonly called the M-series.

Development of the new vehicles began in the late 1940s, though some prototypes and experimental models didn’t appear until the 1950s and ’60s. Some of the earliest types were the Willys M38 and M38A1 jeeps, the Dodge M37 ¾-ton truck and its variants, and the GMC M211 and Reo M35 2½-ton trucks and variants. The M38 and M38A1 were regarded as temporary, as the M151 MUTT, then under development, was slated to replace them. Larger cargo and troop transport trucks were standardized in 5- and 10-ton ranges. It’s interesting that although the 1½-ton trucks of WWII, most notably the Chevrolet G506, had been very useful, that size was apparently dropped from the roster.

While all of the aforementioned vehicles were indeed new designs and considered to be better suited to a possible nuclear war scenario, they were basically just upgraded versions of their WWII predecessors. What the military still envisioned were high-mobility vehicles built especially for operating in a nuclear-devastated environment. On a very large scale this concept was tested with the Land Train cargo vehicles, of which three were built by the LeTourneau Company, but designs for a 1½-ton vehicle were also being considered, which led to the conception of the M561 Gama Goat.

Though it seems that actual plans for such a vehicle had yet to be finalized, in 1961 a Swiss-made articulated 6x6 vehicle called the Metrac was tested at Aberdeen Proving Grounds. Although it performed well, the Metrac had a rather complicated hydraulic suspension system. Still, the officials decided it was something along the lines of what they were looking for, and surely good old American know-how could build something better… and it would be amphibious.

That, of course, remained to be seen.

The Clark Equipment Company, manufacturer of forklifts and other industrial equipment, was granted a license to develop a home-grown version of the Metrac for the U.S. Army. Ironically, this high-tech vehicle used the same Willys F-head engine as the M38A1 jeep. However, the new vehicle’s Metrac-based hydraulic suspension proved to be troublesome, so a contract was offered to the Chance-Vought Aircraft Company to develop another six-wheel-drive articulated machine. Chance-Vought discarded the hydraulic suspension in favor of independent coil springs on the front and rear axles with a swing-arm setup similar to that of the M151 MUTT, while the center axle used a traverse leaf spring. Possibly because Chance-Vought was an aircraft company, this vehicle had an all-aluminum body. It was powered by a Chevrolet Corvair six-cylinder “pancake” air-cooled engine. The Chance-Vought vehicle also featured a new articulation coupling between the tractor unit and the cargo body. This coupling was designed by Roger L. Gamaunt, hence the name “Gama” with only one M as opposed to the Gamma in Gamma rays. This coupling provided power to the rear axle on the cargo unit and permitted the two units to pitch and roll in relation to each another over uneven terrain, but not to swing side-to-side like a conventional trailer.

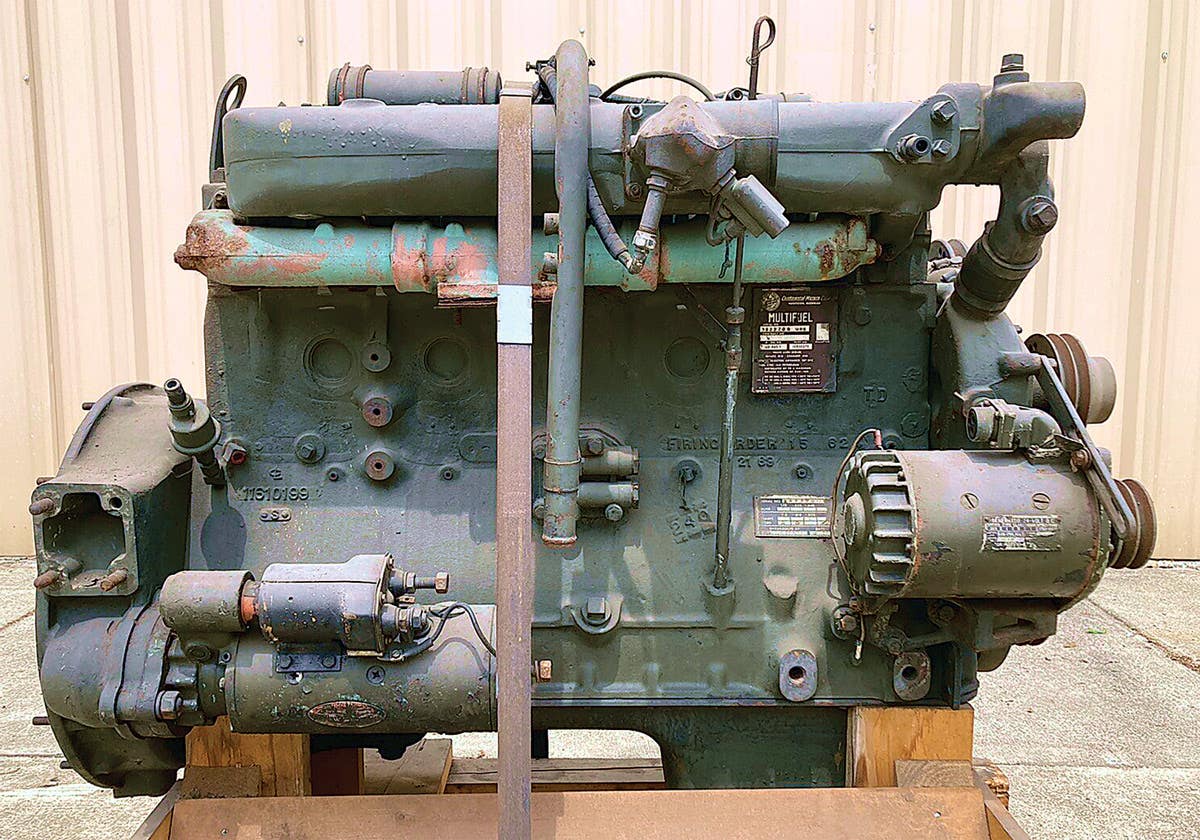

Like the Metrac-copied Clark prototypes, the Chance-Vought vehicles had problems, but the U.S. military apparently had the hots for this design and its solution was to throw money at the problems. In keeping with the desire of having many M-series vehicles with either diesel or multifuel powered engines, the Corvair engine was replaced with a G.M. (Detroit Diesel) 3-53, a three-cylinder, two-cycle engine that displaced 53 cid per cylinder. This engine differed from the commercial models by having an aluminum block and head. If the reader has had any experience with two-cycle GM diesels, it isn’t necessary to mention their noise. Right from the start of testing, drivers complained about that distinctive Detroit Diesel scream, so much so that even the General Accounting Office began to question the Gama Goat project.

Nevertheless, the money tap continued to flow and, in 1966, the Gama Goat design was finalized and the vehicle was designated the M561. Chance-Vought’s contract had been for development, not production, so bids were opened for other companies to build the Goat. Although Chance-Vought (which had merged with Ling-Temco Electronics to become LTV Corporation) and Kaiser Jeep Corporation (formerly Willys Overland) bid for production, Consolidated Diesel-Electric Company (CONDEC) was awarded the contract. (CONDEC also built the LARC V amphibian, the M123A1C ten-ton truck, and the M747 tank-transport trailer.) The Gama Goat contract called for 14,000 M561s to be built at a cost $5,000 apiece, which would be around $50,000 in today’s money. Not bad for a highly specialized military vehicle? No, except the actual cost per unit turned out to be $15,000 or about $150,000 today. In contrast, Dodge M37B1s were still being built at around $5000 each. One might say that red warning flags were starting to wave.

As production began at CONDEC’s Schenectady, N.Y., and Charlotte, N.C., plants, a barrage of red rockets shot up! The original specifications called for a curb weight of 2,500 lbs. In reality, the M561 weighed almost 7,500. The first 11 Goats to come off CONDEC’s assembly lines had so many defects they were sent right back to the factories. The M561 was supposed to be able to travel at least 10,000 miles with no major mechanical problems. Yet, after years of development on this new post-apocalyptic wonder, as well as millions of dollars spent, the military settled for...”An average combat mission of 75 miles... 95 percent of the time!”

Thankfully for the world -- at least thus far -- a nuclear war hadn’t happened, and the M561 arrived just in time for the Vietnam conflict. Problems continued to surface as Goats took to the field, and the troops were less than enthusiastic about this new machine. For one thing, a driver and co-driver didn’t so much get into a Goat, instead they sort of put it on. Getting in and out in a hurry was so difficult that operators worried about being trapped in an ambush. The M561 was supposed to be amphibious, or at least be able to swim in calm water. However, it was soon discovered that Goats fitted with a front-mounted winch and swimming with an empty cargo unit tended to take nose-dives into Davy Jones’ locker; and like the Ford GPA of WWII they were useless for surf landings on ocean beaches. Additionally, the Goat relied upon a rubber gasket to seal the cargo carrier’s tailgate, and this gasket was a constant source of trouble. In a word, it leaked. Swimming Goats that were loaded often simply sank without much warning. Even worse, the tailgate itself was flimsy and couldn’t stand up to the loading and unloading of cargo.

The tractor unit was equipped with a bilge pump, but the cargo unit was not, which seems like an example of bad engineering because the interior of the cargo unit could not be seen by the driver. One would have thought that for this reason alone, the cargo unit would have been fitted with a pump. The driver had to be extremely careful when entering the water from any kind of slope: if entry was too fast (over 2 mph) the vehicle’s nose would simply go under. Trying to leave the water on a steep slope would often sink the carrier unit. The maximum wave height for safe water operation was only 6 inches. Propulsion in the water was accomplished by the wheels spinning in a frantic and messy way with a top speed of about 3 mph. Steering in the water was also done by the wheels, and response was very poor. A Goat was totally helpless in any kind of current. Goats sank so frequently, that an order was issued never to swim with the tractor canvas in place. Likewise, the cargo carrier canvas was removed if troops were aboard. A “surfing kit” with shields was developed for the Marine Corps Goats, but it did little except make it even harder for the driver and co-driver to enter and exit.

Drivers of the prototype Goats had complained about the noise from the 3-53 engine, and the field operators were just as vocal with their criticism in this respect. Added to the complaints was the fact that it was impossible to hear commands above the engine’s scream, issuing ear plugs certainly didn’t improve matters! Soldiers also complained about the uncomfortable driving position, as well as the aforementioned difficulty of getting in and out of the vehicle.

While the M561’s four-speed manual transmission had been lifted directly from a Chevy or GMC civilian truck, it had a complicated and poorly-designed linkage that was often hard to shift and tended to jam. Goats also had a nasty habit of snapping axle shafts and universal joints when loaded or stressed, though simply popping the clutch often produced the same result and could get a soldier out of the miserable duty of driving a Goat. This was a frequently employed tactic in Vietnam; and it was pretty hard for a furious second lieutenant to prove that a soldier’s muddy jungle boot hadn’t just slipped off the clutch pedal. Speaking of mud, the Gama Goat’s wheels threw mud everywhere, including on the driver, co-driver, the troops in the carrier, and on the windshield to such a degree that this alone was considered to be a driving hazard. If there was ever a U.S. military vehicle voted most likely to be fragged, it was the M561. The author has heard several tales of Goats being deliberately rigged so their parachutes wouldn’t open during air-drops.

It was also soon discovered that the Goat’s thin aluminum underbelly was easily punctured by rocks and other road hazards, therefore losing whatever marginal swimming ability it possessed. The entire body was rather flimsy and was easily battered, dented or bashed out of shape. The windshield did not fold down, though it was fairly simple to remove. However, it was also flimsy and was often bent or cracked by soldiers getting in or out of the vehicle. The front bumper, a light aluminum I-beam, was basically a joke, and had to be replaced so often that stock ran out while the M561 was still in service.

Repair and maintenance proved to be yet another major headache for the soldiers who had to service Goats. Many components as well as lubrication fittings were difficult to reach; and to replace or unclog the bilge pump required that the engine be pulled. The main transmission was within the body and was located in the vicinity of the driver’s right elbow, while the two-speed transfer case sat at the driver’s right knee. The transfer case was connected directly through the hull to the front axle differential, which added an echo effect to the noise factor when traveling. A double universal joint coupled the transmission and transfer case, while a lower drive shaft — also within the body — ran back under the engine to the center axle differential, which was at the rear of the tractor unit. From there, another drive shaft came out astern and coupled through the articulation joint to drive the cargo body’s axle.

In two-wheel-drive for highway operation, power went to the center axle alone. For all-wheel-drive, a lever atop the transfer case engaged the front axle, and also via a linkage rod shifted the center axle differential to engage the cargo body’s axle. The adjustment of this linkage was critical to ensure that both front and rear axle shifting was simultaneous and complete. A second lever on the transfer case was then used to select either high range, low range, or neutral.

In keeping with the Goat’s complex design, the transfer case had a small external piston pump that forced gear oil through a copper line to lubricate the upper gears and bearings. If this pump lost its prime or otherwise failed, the transfer case would quickly self-destruct. A field modification called for cutting out a short section of the oil line and clamping on a piece of clear plastic tubing so the driver could see if the pump was working. However, the tubing quickly turned yellow and became useless as an indicator. B

efore setting off on a mission, it was SOP to put the transfer case in neutral with the engine running, shift the transmission into gear, then loosen one of the oil line fittings to check if the pump was working. Of course, if the pump failed while on the road, one usually didn’t know until the transfer case seized up. As mentioned earlier, the transmission’s shift linkage was a constant source of trouble. If it was adjusted perfectly, the transmission would shift okay about 50 percent of the time. The most common problems were getting reverse when the driver wanted second gear — or vice-versa — and an almost certain gear grind between second and third.

Driving an M561 required quite a bit of training, because the rear wheels steered in conjunction with the front, which sort of pivoted the vehicle right or left on its center wheels. While the cargo body was free to pitch up and down, as well as roll in lateral relation to the tractor unit, it did not swing from side to side like a trailer. Most driver’s instincts were to try and back up as if the carrier unit was indeed a trailer, but this didn’t work. While the rear wheels only turned about 50 percent in relation to the front, a driver could still run into trouble with tail swing. This could make a Goat very dangerous on a narrow mountain trail, while in traffic having the Goat’s tail swing in the opposite direction from the front could shave the paint off another vehicle.

If one had driven a long vehicle or towed a trailer, it had usually become second-nature to swing wide around corners. However, with a Goat, one always had to remember to cut their corners tight. While late production Goats had power steering, most did not. The vehicle required considerable steering effort, especially at low speed and off road. The steering system was not well designed or built, and its small universal joints tended to snap when stressed. While the Goat had positive traction on all axles, this made it crab and skate a lot when driven on slick mud or ice, and also allowed it to quickly dig six graves for its wheels in soft terrain. Other common faults were snapping the double universal joint between the transmission and transfer case and/or the universals on the center axle drive shaft in low gear two-wheel drive.

By 1972 problems in manufacturing and performance of M561 vehicles had led to an inquiry by a House Armed Services Subcommittee. The following are excerpted comments reported in two different columns in the August 9, 1972 issue of Army Times. “After years of frustration and tests, the Army has fielded a vehicle $10,000 more expensive than planned. It features a bad design, sloppy craftsmanship, operational, maintenance and other problems. While racking up repeated test failures, the Army nonetheless continued to produce the Gama Goat. The first 4400 vehicles were delivered to Army depots to await correction of major defects. Those vehicles are still awaiting retrofit of defective gears manufactured by a foreign subcontractor.

The problems were so numerous that the Army changed its reliability requirements: instead of requiring that the M561 go 10,000 miles without a major component failure, the new rules said it had to have a 95 percent chance of going 75 miles without breaking down. The first 4400 vehicles were delivered, but testers and operators reported hundreds of deficiencies ranging from the complete absence of a rear driveshaft assembly to stripped gears and leaky brake cylinders. The 4400 Goats were put in storage, to be retrofitted later.”

High Mobility Multipurpose Wheeled Vehicle (HMMWV). Steve Turchet

All in all, and despite the high hopes of its designers, the M561 was a quirky, unpopular, high-maintenance vehicle that, except for its marginal swimming ability, could do very little that couldn’t be done just as well or better by an M37, M715 or a deuce. M561 vehicles were finally phased out of the U.S. military inventory during the 1980s and were ultimately replaced by the M998, 4x4, High Mobility Multipurpose Wheeled Vehicle (HMMWV).

One might conclude it was fortunate that the M561 didn’t have to be relied upon during a nuclear war.